MASROOR MALIK, Semiconductor Market Manager, Swagelok Company

As the world quickly adds smart technologies to nearly every facet of life, semiconductors and microelectronics are also advancing to meet the complex needs of an ever-evolving digital landscape. Big data and artificial intelligence are accelerating this growth and are increasingly requiring smaller, more powerful chips, which by necessity means their fabrication will become more challenging.

Manufacturers will face specific considerations as they construct the next generation of advanced technologies. One of the biggest challenges is the need to improve product performance while keeping costs at reasonable levels. These factors indicate a pressing need to meet stricter requirements and adapt to increased high-temperature/high-flow applications through reliable process control.

Greater responsiveness, improved component reliability, and confidence that chemistry can be delivered with maximum precision are becoming more important to customers throughout the industry as its sophistication improves.

Advancing semiconductor manufacturing for the future

The momentum toward a world of “smart everything” continues, and smaller, thinner, and faster devices are in demand. For semiconductor manufacturers, that means precision will continue to be vitally important.

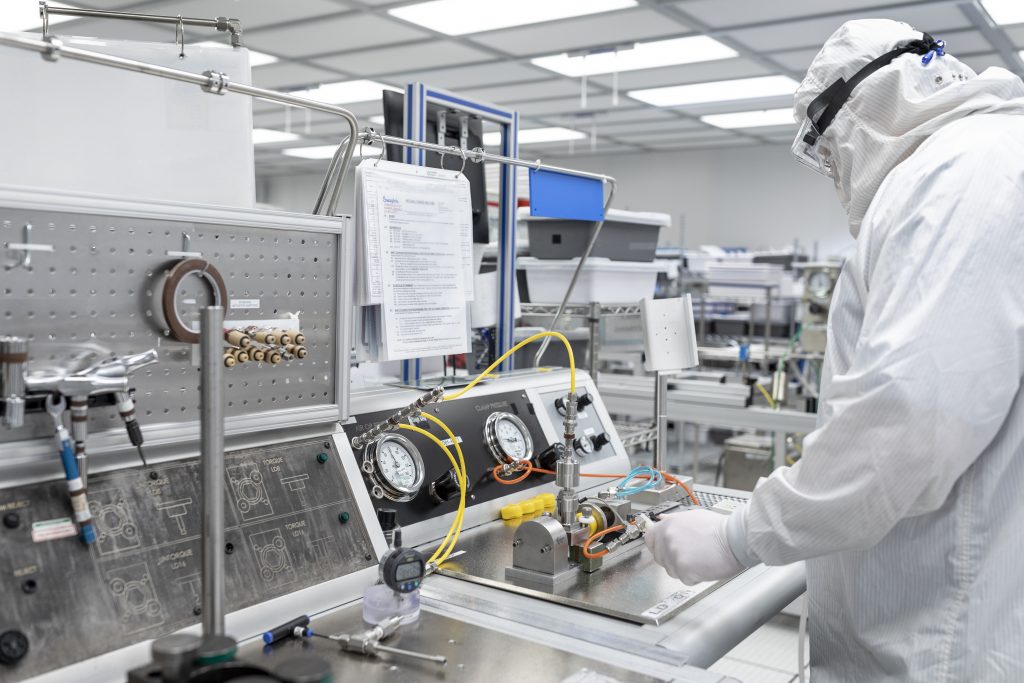

It does not matter what the operating conditions are: The system equipment must allow precise, high-temperature chemical delivery, dosing, and cleanliness. As critical as precision is in the manufacturing of semiconductors, it is equally important in the production of the fluid system components that drive fabrication processes as well (FIGURE 1). Manufacturers will increasingly demand increased control over any process variables so they can remain competitive and meet evolving industry standards.

Repeatability is critical to the semiconductor market, and the elimination of any potential variance or inconsistency in the chip manufacturing process would be welcomed by many. It is important to offer greater thermal control and contamination prevention throughout the process, and precision-produced fluid system components allow that to happen.

In a fast-moving industry where there is little margin for error, it is critical to educate and train your teams so you can have more confidence that you can meet manufacturing goals while maintaining safety protocols.

Read the full article in the December 2021 issue of Semiconductor Digest.