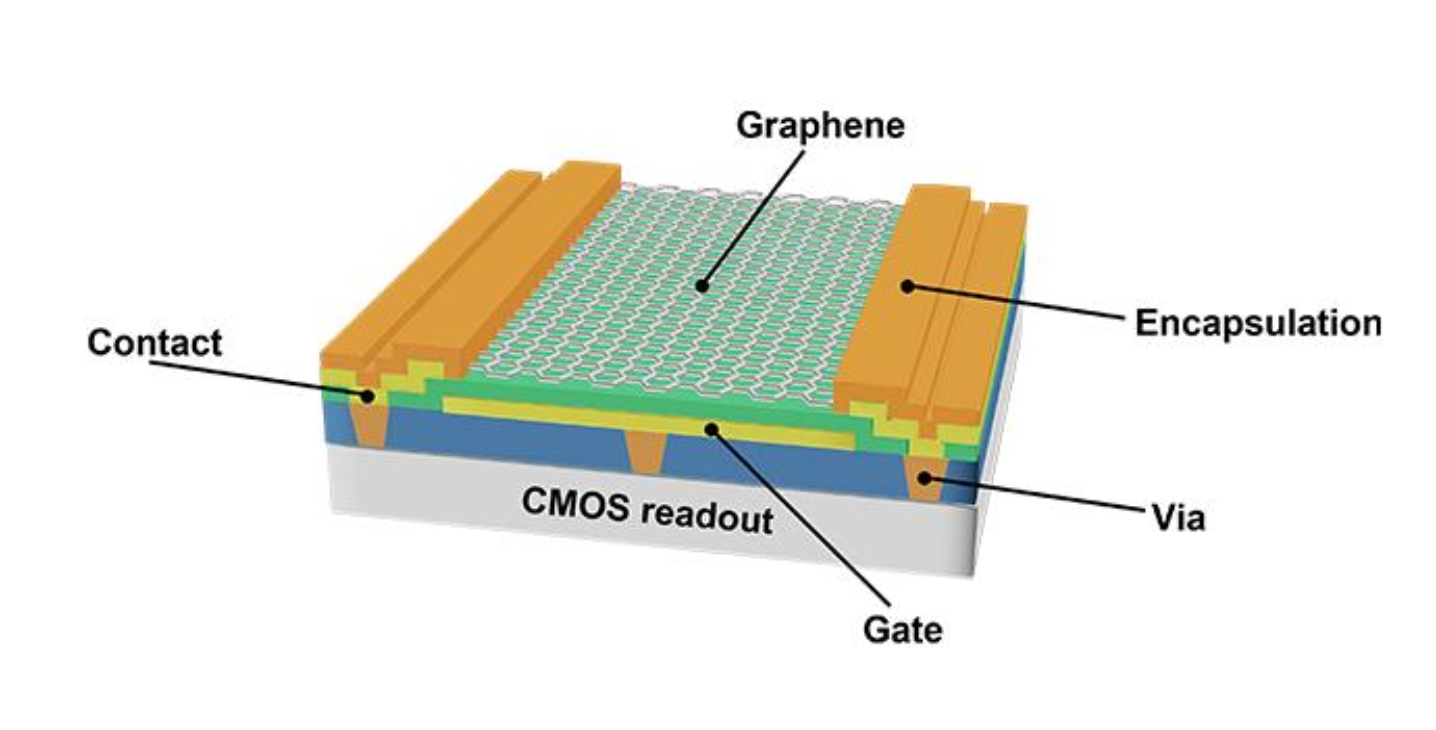

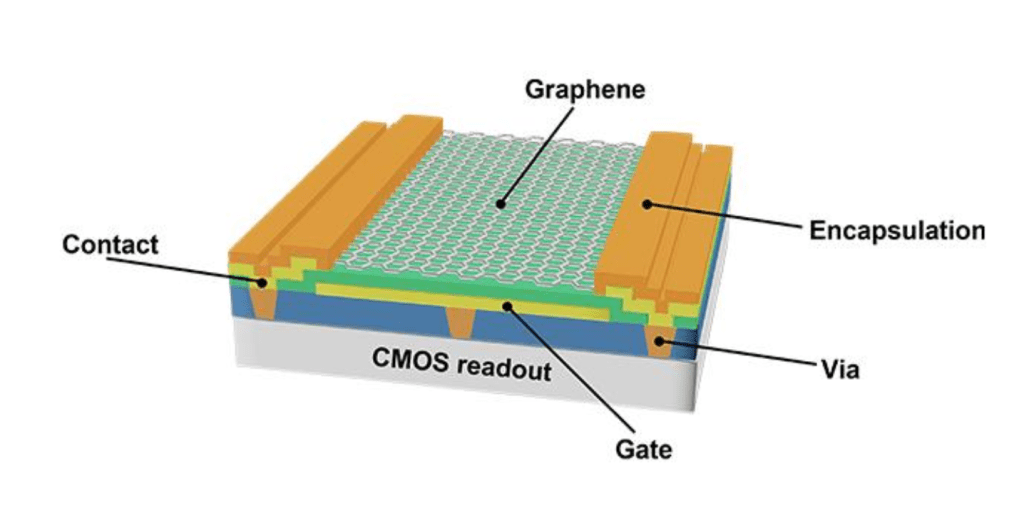

Archer Materials Limited, a semiconductor company advancing the quantum technology and medical diagnostics industries, has sent a new graphene field effect transistor (gFET) design for its Biochip to VTT Technical Research Centre of Finland Ltd for manufacture 200mm diameter wafers via a MPW run for integration with CMOS readout.

The MPW run with Archer’s gFETs integrated directly onto the silicon CMOS chip will measure how effectively Archer’s gFET sensors can be electrically accessed, controlled, and read out by a conventional silicon CMOS circuitry – a standard and ubiquitous technology in semiconductor manufacturing.

Integrating CMOS technology into Archer’s Biochip gFET brings several big advantages:

-

- The CMOS technology minimises environmental interference, making the readings more accurate and faster.

- CMOS integration enables the sensors to handle lots of data simultaneously and process that data, which is important for getting reliable results.

- Archer’s chips will feature 1,024 gFET sensors on a single array. Even if a few sensors experience faults, the chip should still deliver accurate and trustworthy results, minimising the risk of errors.

- CMOS is already a standard and ubiquitous technology, and can therefore be used to integrate Archer’s gFET and biosensors into existing electronic devices, making them more practical for real-world use.

VTT will review Archer’s gFET design to confirm that it meets its requirements for integrating the gFET with CMOS readout into a single chip. VTT will then fabricate and deliver 40 bio sensor array chips to Archer, with each chip containing 1,024 sensors.

The gFETs are designed with structures suitable for liquid multiplexing, with significant advances in chip design features, including gating design and materials, to address technological challenges in maintaining graphene device stability from chip to chip.

Multi-analyte detection, using gFET sensor, benefits extensively from integration of CMOS circuits, as they provide the circuitry to multiplex the control and readout of many gFET sensors. More advanced multi-analyte diagnostic solutions can be achieved on a single chip by using sensor arrays with integrated CMOS readout.

One of the biggest challenges with biosensors like gFETs is ensuring they are reliable and can give accurate results every time. gFET sensors are sensitive and can run into problems like faulty devices, tiny air bubbles, or issues in setting the sensors up.

This latest work builds on earlier gFET design fabrication milestones, including a MPW run with a German foundry (ASX ann. 9 Nov 2023), a whole four-inch wafer run at a foundry in the Netherlands (ASX ann. 14 Sept 2023), and a six-inch wafer run at a Spanish foundry. Archer also recently advanced its Biochip gFET chip design through a significant size reduction, with the miniaturised chip designs sent for fabrication to a foundry partner in the Netherlands (ASX ann. 11 Mar 2024).

Commenting on the gFET test work, Greg English, Executive Chair of Archer, said,

“CMOS is an industry-standard technology that’s used in nearly all modern electronic devices. It’s known for being very efficient and reliable, which is why it’s so widely used.

“By making our gFETs, and ultimately the biosensor, compatible with CMOS, we’re ensuring they can easily work with other electronic systems. This compatibility is crucial because it makes the biosensors more versatile and easier to integrate into different devices and applications for real-world use.”

Archer expects to receive the gFET sensor chips back from VTT in the first half of 2025 and will use the sensor chips to develop multi-analyte biosensors.