Earlier this year when the novel coronavirus, SARS-CoV-2, began sprinting around the world, public health officials told us that social distancing was the most effective way to slow its spread. We’re now many months into the pandemic, and social distancing, combined with mask-wearing, is still the best way to prevent new cases of the disease.

On March 20, 2020, governors on opposite coasts, Gavin Newsom in California and Andrew Cuomo in New York, shut down their states, and other states soon followed. Only essential businesses, such as select retailers – grocery and hardware stores as well as pharmacies, for example – were allowed to remain open. Depending on location, however, it was days or weeks before strict social distancing measures were in place. Tape stuck six feet apart on store floors has helped shoppers keep their distance. But shouldn’t there be a more exact and reliable way to gauge social distances in retail stores, gyms, workplaces and other settings?

David Horsley, founder and CTO of Chirp Microsystems, a TDK Group company, believes so, and the company is developing technology that does just that. Horsley will share the details in his keynote A Wearable Social Distancing Solution Based on Ultrasonic Time-of-Flight Sensors October 14 at MSEC 2020, SEMI’s first virtual MEMS & Sensors Executive. The event is October 6-8 and 13-15, 2020. Register now for MSEC 2020.

I spoke with Horsley to learn more about the sensors.

SEMI: What was the inspiration for providing Chirp’s ultrasonic Time-of-Flight (ToF) sensors for social distancing?

Horsley: Companies actually started contacting Chirp about six months ago to inquire about social distance tags to measure distance between people. They already knew about us because we’ve been supplying MEMS ultrasonic ToF sensors for virtual reality and robotics for several years, so they knew we could provide the same kind of low-power range-finding accuracy for resource-constrained devices.

SEMI: How are your customers using Chirp-based social distance tags?

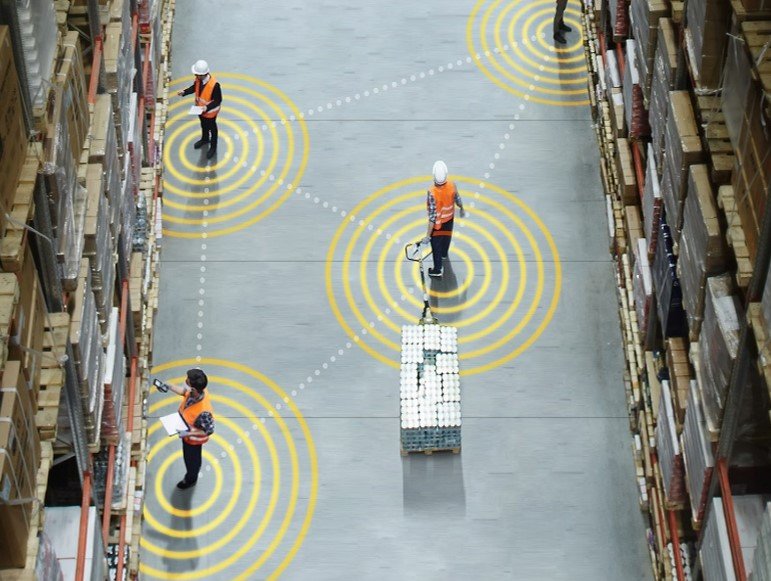

Horsley: They’re designing Chirp’s ultrasonic ToF sensors into wearable tags worn by workers in distribution centers, in factories, and in oil and gas production, to name a few areas. The tags alert workers when they’re closer than two meters from another worker to ensure social distancing.

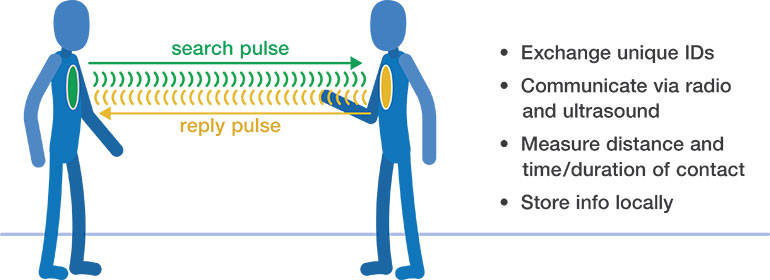

Chirp’s ToF sensors also support contact tracing without recording any personal information, which is a major advantage over contact-tracing applications from companies like Google and Apple. Because those apps use Bluetooth Low Energy (BLE), which is already in your smartphone, the user has to enable location services. This records your GPS location, a privacy concern.

BLE is problematic on some other levels as well. It only provides one-meter accuracy while Chirp’s ToF solution for social distancing delivers one-centimeter accuracy. Because BLE is only accurate within one meter, it can’t alert you in real-time that you’ve crossed that two-meter boundary to another person. Imagine you’re in the checkout line at the supermarket. BLE can tell you that other people are in your general vicinity, but it doesn’t have enough resolution to tell you whether the next shopper is two meters away from you or only one-and-a-half meters away. And because it doesn’t use the air as a medium, it registers a lot of false positives. If, for example, you’re separated from a person by a partition or a wall, and you’re within two or three meters of each other, your phone’s social-distance app will register a false positive.

SEMI: Are you talking with customers in other environments, such as college campuses and theme parks?

Horsley: There’s great deal of potential in those markets. For example, Professor Prabal Dutta’s group at UC Berkeley is working on a system that uses our sensors. His work also made us aware of some of the privacy concerns around contact tracing because universities are much more uneasy about student privacy than some private-sector companies are today.

SEMI: What would you like MSEC attendees to take away from your presentation?

Horsley: From the beginning, we believed that MEMS ultrasound was very versatile. We expected it to find a home in different types of applications because of its low power, small size and ease of use, particularly since we provide the enabling software that makes it all work. With design wins in four to five vertical markets, we’re experiencing significant marketplace validation.

We’re all hoping that COVID-19 will wind down in the first half of 2021. As the focus on social distancing begins to fade, we’re looking forward to building out our customer base in the markets we’re in today as well as gearing up to explore new markets.

Chirp Microsystems and TDK InvenSense are longtime members of MEMS & Sensors Industry Group® (MSIG), a SEMI technology community that connects the MEMS and sensors supply network in established and emerging markets, enabling members to grow and prosper. Visit us today to learn how MSIG membership can make a difference in your business.

David A. Horsley, Ph.D., is co-founder and CTO of Chirp Microsystems Inc., a TDK Group company. Horsley is also a professor of Mechanical and Aerospace Engineering at the University of California, Davis, and is adjunct professor of Mechanical Engineering at the University of California, Berkeley. Since 2004, he has been co-director of the Berkeley Sensor and Actuator Center (BSAC), the National Science Foundation’s Industrial/University Collaborative Research Center (I/UCRC) focused on MEMS research. Horsley is also a recipient of the National Science Foundation’s CAREER Award, and has authored or co-authored over 150 scientific papers and holds over 20 patents.