The energy-hungry nature and large carbon footprint of semiconductor manufacturing have received considerable attention in the context of reducing our emissions of planet-warming greenhouse gases. It turns out we are just as thirsty as we are hungry.

Sustainability Through Collaboration

IPCC 6th Assessment Report Working Group III – Mitigation

The evidence is clear: the time for action is now. We can halve emissions by 2030.

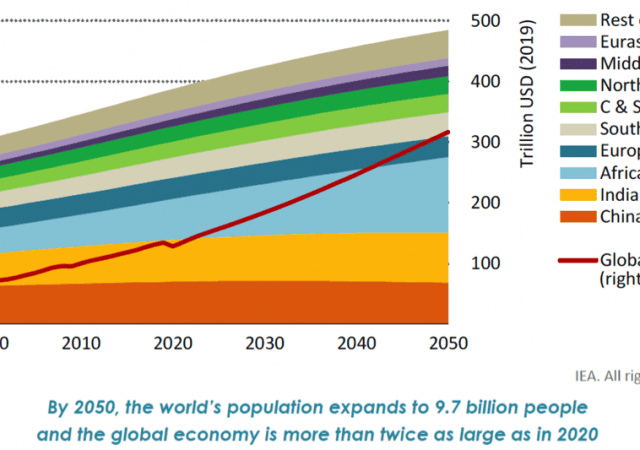

Net-Zero by 2050 – A Roadmap for the Global Energy Sector

By Chris Jones, Edwards Vacuum This post will look at highlights of a similar report written by the International Energy Agency (IEA), which examines the issues through a more global lens.

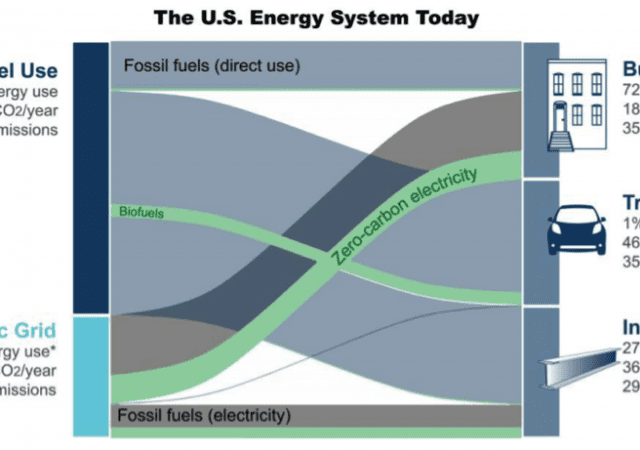

Roadmap to Decarbonizing Electrical Power in the United States

By Chris Jones, Edwards Vacuum The International Technology Roadmap for Semiconductors (ITRS) and its successor, the International Roadmap for Devices and Systems (IRDS), have played a central organizing role in the development of the semiconductor manufacturing industry since the first ITRS was published in 1993.

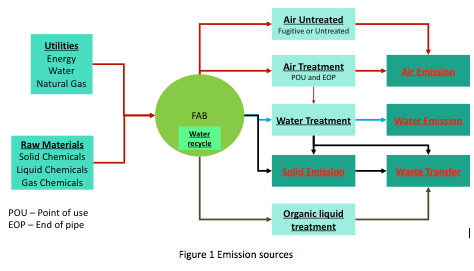

Sustainability in Semiconductor Manufacturing – A Review of Emissions and Materials Released Off-Site

By Chris Jones, Edwards Vacuum In the last post to this blog, we introduced the theme of sustainable manufacturing, which will be our ongoing focus. We described the evolving framework for limiting carbon emissions and reviewed the vocabulary we will use going forward. This post will briefly overview the materials released off-site during semiconductor manufacturing – what they are, where they come from, and where they go.

Sustainable Manufacturing

Regular followers of this blog will notice a shift in focus with this post. For the last year or so we have covered issues related to service and support for vacuum and abatement systems that enable semiconductor processes. With this post we will shift our focus to the more general topic of sustainability in semiconductor manufacturing.

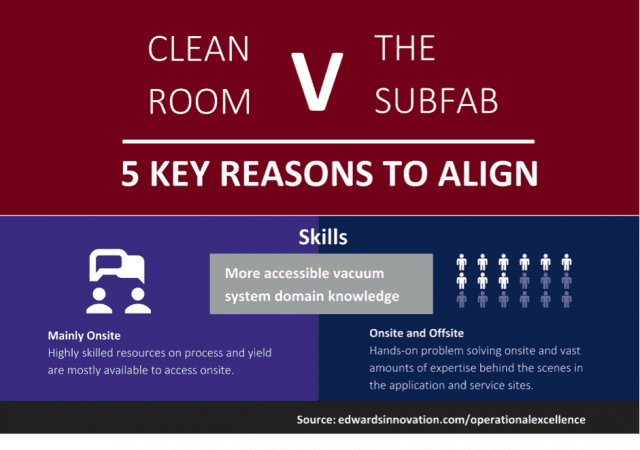

Driving Fab Performance Metrics from the Sub-Fab to the Cleanroom

By Alan Ifould This is the 10th post to this blog in a year where change has been an overriding theme.

Shaping the Future Innovations of Maintenance – Part 2: Connecting the Creativity of Humans

By Alan Ifould In our last post to this blog, we described Edwards’ service maturity model*, which establishes a framework for understanding the service and support approaches most appropriate for customers based on their position within an evolutionary hierarchy that goes from run-to-fail to preventative, predictive, and, ultimately, prescriptive maintenance models.

Shaping the Future Innovations in Maintenance – Part 1

By Alan Ifould At a time of renewed focus on digital transformation, business leaders are seeing just how importantoperational resilience is when meeting performance objectives. Fast and flexible operations from the clean room to the subfab are propelling customers ambitious growth targets, but how are customers navigating this landscape of change and where remains the unlocked potential?

Developing People and Skills to Bring Vacuum and Abatement Domain Knowledge to the Forefront of Semiconductor Manufacturing Processes

By Alan Ifould This post looks at how we train and motivate people to strive for excellence in their own environment and in collaboration with others, drawing heavily on insights from Richard Swayne, Head of Training and Development at Edwards.