By Alan Ifould, Edwards Vacuum

Surely it is lost on no one that the name of this blog, and the name of this post, “Upstairs, Downstairs”, is a reference to the cleanroom and the sub-fab. You probably also get the allusion to the iconic BBC television series (I must admit it brings back happy childhood memories of Sunday gatherings to watch the latest episode), which tells a tale of two worlds that, like the cleanroom and sub-fab, are fully separated but inevitably interdependent.

As in the TV series, it is the cleanroom, upstairs, that gets most of the attention. But the cleanroom cannot function without the sub-fab, downstairs. Without the sub-fab’s essential services and support, operations in the cleanroom come to a sudden and costly halt. The differences between upstairs and downstairs are many, but in some of those differences lie opportunities to improve yields, reduce downtime, avoid scrapped wafers, decrease maintenance costs, increase productivity and profitability, and more.

Edwards is uniquely positioned to understand the differences between the cleanroom and sub-fab. Our vacuum pumps and abatement systems fill semiconductor manufacturing facilities around the world, ranging from turbo- and cryo-pumps on process chambers in the cleanroom to dry pumps and abatement systems in the sub-fab. Click here or on the figure at the top of this article to download the full infographic “Cleanroom vs the Sub-fab and the 5 key reasons to align”.

Processes – Before exploring the differences between the sub-fab and cleanroom it is good to remember what ties them together: the semiconductor process used to create integrated circuits. Of course, the process is really many processes, all involved in a repetitive sequence of deposition, etching and cleaning, applied over and over again to a single wafer to create the patterned layers that constitute an integrated circuit. Each process has unique requirements for the environment in the process chamber, but ultimately the pumps in the cleanroom and the pumps and abatement systems in the sub-fab see the same process gases and by-products. In the process chamber, these gases enable the atomically precise deposition and removal of material that creates the integrated circuit. Downstream however, in the pumps and abatement systems used to extract and neutralize process exhaust, the deposits and material removal caused by these gases can degrade performance and, left uncontrolled, shut down the entire process. The fact that the cleanroom and the sub-fab execute and manage different aspects of these processes, like the occupants of the Upstairs Downstairs house, drives similarities and differences in equipment, maintenance, measurement, and people

Equipment – The cleanroom is typically filled with a wide variety of process tools from many different manufacturers. The range of on-tool vacuum pumps is equally broad: fast pump-down of a load lock may need a compact dry pump, an etch chamber might be best served by a turbo-pump, while the ultra-high vacuum in an ion implanter or a sputtering tool may require a cryo-pump. Despite a considerable degree of standardization in some areas, like wafer handling and wafer transport, the variety and complexity of process tools and operating interfaces in the cleanroom makes providing vacuum and support more complicated there than in the sub-fab. The grouping of tools by process – etch, implant, lithography, etc. – and the isolation of processes in silos, adds further complication and hinders optimization with fleet management strategies.

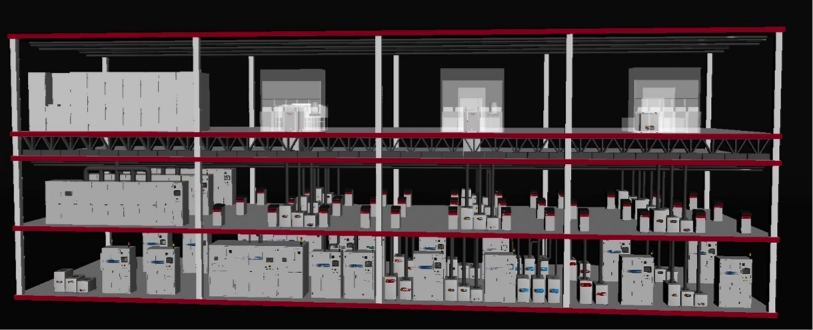

Not all cleanroom tools require on-tool vacuum pumps, but almost all rely on vacuum and abatement services in the sub-fab. In contrast to the cleanroom, the sub-fab, is usually a large open space packed with vacuum pumps, abatement systems, and other mission-critical equipment that have much in common with one another in both design and operation. In many cases, a single manufacturer may supply all the vacuum and abatement equipment at a site. This similarity among systems lends itself well to a fleet management approach. But the similarity can also be misleading: under the covers, the variations in the fleet reflect the complexity and variety found in the fab. Vacuum and abatement equipment behave differently from process to process, depending on the type of process (deposition, etching, or cleaning) and the specific materials and gases used. Equipment selection is critical – choosing the wrong pump or abatement system or making poor maintenance decisions creates at best inefficiency, at worst process downtime and critical safety hazards. Fleet management can be effective, but attention to detail and expert support is just as important as in the cleanroom.

Maintenance – In the cleanroom, the physical constraints of the large integrated process tools means maintenance is almost always performed on-site, requiring highly skilled technicians, sometimes including the engineers who designed and built the equipment. Process tool maintenance is typically managed on a fixed-interval or run-count basis, usually established through experience, although increasingly, condition-based analytics are driving maintenance decisions. Exacting demands for process-control require extensive instrumentation to constantly monitor tool conditions between fixed-interval or run-count maintenance procedures.

In the sub-fab, technology advancements have allowed service intervals for vacuum and abatement equipment to become much longer than those for process tools. Maintenance regimes vary – abatement systems are usually maintained on-site, while pumps are typically removed and maintained off-site. For this reason, much of the support network is also off-site. Some critical pumps and abatement systems are maintained on a regular schedule, but maintenance tends to be reactive – sometimes even run-to-fail, with back-up pumps at the ready. This dilutes the benefit of the longer service intervals and can cause unplanned tool downtime. But should it be that way? Can we do better to learn from the way process tools are managed?

Measuring – Differences in the way vacuum equipment is monitored and measured in cleanroom and sub-fab reflect of the different aspects of the process they address. In the chamber, process vacuum is critical and process engineers constantly monitor vacuum levels, check for leaks with residual gas analyzers (RGA) and helium leak detectors, and detect process endpoints with in-chamber RGA and optical emission spectroscopy. Most of these vacuum sensors are add-ons, typically not natively integrated with the process tools. Additional monitoring tracks thousands of wafers through complicated process flows with frequent measurements and inspections to confirm process performance. Atomic-scale precision and control requires thorough measurement and characterization of all aspects of the process, and the cleanroom operational paradigm is inherently data intensive.

Sensors for sub-fab vacuum equipment are typically integrated, with many hundreds of relevant vacuum and abatement parameters monitored and available through equipment controllers. This can go up to thousands of parameters for the most complicated equipment, such as those supporting EUV lithography tools. This represents a significant data set that needs to be integrated with fab process data. But in the sub-fab, we have yet to take full advantage of the insights we might derive from this data. Smart Manufacturing initiatives are now making inroads into this potential, and we expect to realize great value in the years ahead.

People – Creating integrated circuits requires many people with a wide range of skills and both theoretical and hands-on knowledge. These skills range across physics and chemistry, materials science, electrical engineering and electronics, mechanical engineering, control systems and more. The skill sets and people needed again reflect the different aspects of the process carried out in the cleanroom vs the sub-fab. In the cleanroom, operators, technicians, and engineers are highly skilled – PhD’s are not uncommon.

On-site sub-fab personnel are also highly skilled, particularly in view of the risks posed by hazardous materials, but because much of the maintenance is performed off-site, there is also an army of highly skilled technicians and PhD engineers working behind the scenes at the service and manufacturing facilities. This PhD level knowledge of process chemistries and vacuum physics is crucial in designing both equipment and maintenance procedures, and, when needed, in solving problems on site. As a significant amount of the sub-fab’s domain expertise is based off-site, maintenance complexity is hidden and opportunities to optimize its effectiveness are often overlooked.

Opportunities – So, what are the shared lessons and opportunities for alignment between cleanroom and sub-fab?

- Adopt a more holistic approach– The cleanroom could benefit from reducing the silos between tools and process areas, harmonizing control interfaces where possible across OEM tools, and adopting a more holistic view that includes interactions between cleanroom and sub-fab vacuum systems. This will probably require the development of standards.

- Increase integration of data measurement in the sub-fab – Even though many parameters are already monitored, there are additional opportunities to collect data in the sub-fab. For instance, vibration sensors and vibrational analysis could provide a wealth of information about the condition of rapidly rotating pump components. Analysis of the composition of the exhaust stream could help to predict maintenance needs and detect problems like leaks. Chemical sensing on the intakes and exhausts of abatement systems could provide valuable operational input and confirm the destruction of hazardous material.

- Transition the sub-fab to predictive/prescriptive maintenance – Predictive maintenance (PdM) and Prescriptive Maintenance (known as RxM) should be the goal for both cleanroom and sub-fab, as befits a Smart Manufacturing enabled environment. A key benefit of PdM is its ability to turn unscheduled downs into scheduled downs. Although a scheduled down has costs, it can be significantly less costly than an unscheduled down. RxM goes one step further, looking ahead to recommend maintenance actions that could delay or prevent a down event. The aggregated effects and cost-savings of reducing or eliminating unscheduled downs across a fab with thousands of pumps and abatement systems can easily run into millions of dollars per year.

- Coordinate planned maintenance between cleanroom and sub-fab – When a need for maintenance in the sub-fab is predicted, scheduling it to coincide with planned tool maintenance in the cleanroom reduces process downtime, improves productivity, and increases profitability. This will require better coordination among different data management platforms in cleanroom and sub-fab.

- Facilitate the access of domain knowledge for field personnel – Sub-fab equipment manufacturers must strive to make their domain expertise readily accessible to field service personnel.

A central theme emerging in the sub-fab is the critical importance of domain knowledge and process data – how it is collected, where it is stored, how it is best used and shared. Many questions about ownership and use remain unresolved. For instance, given the high value of domain knowledge in any service and support organization, should providers be free to fix any problem they have seen before? If it is your pump that is failing you are likely to say, “Yes, of course, fix my pump.” If it is your competitor’s pump that is failing and your facility where the problem was first seen and solved, you might answer differently. Which answer is best for the industry? This will be the focus of our next blog.

To share a quick summary of this blog with your colleagues, download the Infographic “Cleanroom vs the Sub-fab and the key reasons to align” from the Edwards Operational Excellence web site here.

Acknowledgements – I want to thank my colleagues Paul Matthews and Erik Collart for their valuable insights and contributions to this discussion.