By Dr. Alissa M. Fitzgerald, founder and managing member, A.M. Fitzgerald & Associates, LLC

When developing industry forecasts, market analysts gather data from hundreds of companies to provide actionable insights on established technologies and to identify near-term business opportunities. As a developer of new MEMS and sensor technologies for a range of commercial applications, clients often ask us, “What’s going to be hot?” Gauging the promise of emerging technologies that are five to 10 years from commercialization requires taking a different tack.

History tells us that most of today’s blockbuster MEMS products were born as academic research projects. Years of hard work by entrepreneurs, funded by millions of dollars, have turned proof-of-concept research into new commercial products. To identify up-and-coming technologies, we gather information straight from the source: academic conferences and articles.

Chirp Microsystems is a good proof point of our research methodology: In my 2012 report on emerging technologies, I highlighted research from UC Berkeley and UC Davis on “In-Air Ultrasonic Rangefinding and Angle Estimation Using an Array of AlN Micromachined Transducers.” Soon after publication, the authors incorporated Chirp Microsystems to commercialize their technology for gesture- and fingerprint-recognition applications.

After five years of development work, Chirp’s products are entering the marketplace. In February 2018, the global supplier TDK InvenSense acquired Chirp, underscoring the company’s commercial potential. At October’s SEMI-MSIG MEMS & Sensors Executive Congress in Napa, Calif., Chirp’s CEO, Dr. Michelle Kiang, held attendees rapt as she described her company’s journey from startup to wholly owned subsidiary.

There’s a method

This year, I reviewed over 100 papers from top researchers presenting noteworthy technologies at the Hilton Head Workshop on Solid-State Sensors, Actuators and Microsystems. My criteria for selection were: commercial relevance; offers a solution to a known or anticipated problem; and technology game-changers. The following caught my eye:

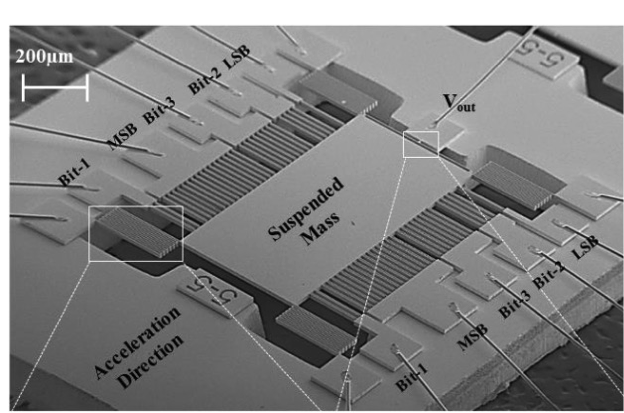

- Event-driven sensors: Cleverly designed silicon MEMS that consume no power while standing by. A triggering mechanical or thermal event closes a contact within the sensor to activate its circuitry and telemetry. These sensors leverage existing fabrication methods, so they could become commercial products within five years for event monitoring and security applications. (UT Dallas, Northeastern University)

- Thin film piezoelectric resonators: Advances in PZT deposition methods and process integration with CMOS were used to create monolithic acoustic waveguides for RF filtering in 5G applications. This new filter design, using existing scalable processes, is ripe for commercialization. (Purdue University, Texas Instruments)

- Intra-body communications: MEMS ultrasound transceivers, made from aluminum nitride, can send data directly through flesh at Mbit/s data rate. With trends toward networks of multiple implanted or wearable medical devices, this innovation would enable medically safe, secure, intra-body wireless communication. This early-stage work still needs in vivo validation and would likely require 10 or more years for development and regulatory approval. (Northeastern University)

- Screen- and 3D-printed sensors: One example of many exciting innovations using screen- and 3D-printing are potentiometric nitrate soil sensors. Low-cost and biodegradable, these sensors could be spread over huge areas to monitor a farm’s soil quality. Table-top and hobbyist tools are currently used to make screen- and 3D-printed devices, so new manufacturing equipment and infrastructure must be developed before commercial production could occur. (Purdue University)

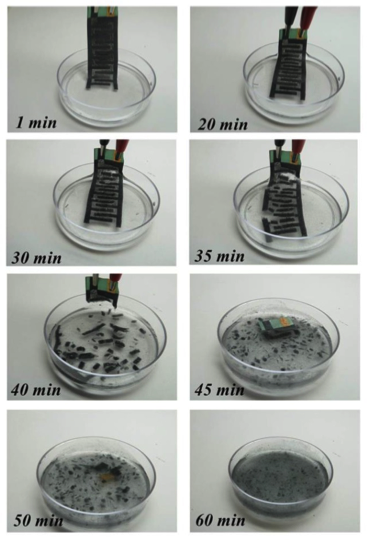

- Biodegradable batteries: A paper-based battery that can deliver 0.5 uW of power, ingeniously using bacterial metabolism as the electrolyte. These batteries dissolve in water and could one day be used to power temporary medical implants or biodegradable sensors. This exciting proof-of-concept prototype will require significant process development and new manufacturing infrastructure

To read more about these technologies, please download my presentationfrom SEMI-MSIG’s MEMS & Sensors TechXpotat SEMICON West 2018.

Alissa M. Fitzgerald, Ph.D., is the founder and managing member of A.M. Fitzgerald & Associates, LLC, a MEMS and sensors development company in Burlingame, CA. She has over 20 years of engineering experience in MEMS design, fabrication and product development and now advises clients on the entire cycle of product development, from business and IP strategy to manufacturing operations. She is a frequent speaker at industry conferences and currently serves as a director of the Transducer Research Foundation, sponsor of the Hilton Head Workshop.She received her bachelor’s and master’s degrees from MIT and her doctorate from Stanford University in Aeronautics and Astronautics.

For more information, visit: www.amfitzgerald.com