EV Group (EVG), a supplier of wafer bonding and lithography equipment for the MEMS, nanotechnology and semiconductor markets, today unveiled MLE™ (Maskless Exposure), a revolutionary next-generation lithography technology developed to address future back-end lithography needs for advanced packaging, MEMS, biomedical and high-density printed circuit board (PCB) applications. The world’s first highly scalable maskless lithography technology for high-volume manufacturing (HVM), MLE combines high-resolution patterning with high throughput and yield, while eliminating the significant overhead costs associated with photomasks, including mask management and maintenance infrastructure. Furthermore, MLE delivers unsurpassed flexibility to enable extremely short development cycles for new devices.

MLE technology accommodates any wafer size up to panels and supports all commercially available resists through a tightly integrated clustered write-head configuration and multi-wavelength high-power UV source. Throughput is independent of layout complexity and resolution, and MLE achieves the same patterning performance regardless of photoresist. MLE complements EVG’s existing lithography systems, targeting new and emerging use cases where other approaches face scalability, cost-of-ownership (CoO) and other limitations.

EVG is now offering demonstrations of its MLE technology at the company’s headquarters. MLE will be incorporated into a new line of EVG systems, which are currently in development and will be announced in due course.

“Our new MLE technology excels in back-end lithography applications, where other patterning technologies, such as steppers, have to compromise on performance or cost. No longer will customers need to choose between resolution, speed, flexibility or cost of ownership for their back-end patterning needs,” stated Paul Lindner, executive technology director at EV Group. “Early development work with an exclusive range of customers has shown that the applications benefiting from MLE are wide ranging and growing in number. As we ramp up the development of this unique exposure technology into first products, we look forward to partnering with more companies across the industry to support new devices and applications that will benefit from MLE.”

Back-end lithography faces new challenges

As heterogeneous integration becomes an increasing driving force in semiconductor development and innovation, impacting the advanced packaging, MEMS and PCB markets, back-end lithography requirements are growing. In advanced packaging, for example, the minimum resolution requirements for redistribution layers (RDL) and interposers with their continuously denser lines/spaces (L/S) are becoming increasingly stringent. In some cases, they are approaching or exceeding two microns, while die placement variation and the use of cost-efficient organic substrates require more flexibility in patterning. The requirements for higher overlay accuracy as well as high depth of focus in vertical sidewall patterning are also growing. New requirements, such as minimizing pattern distortion and die shift due to wafer distortion in fan-out wafer level packaging (FoWLP) and support for thick and thin resists, are just some of the criteria for existing and future advanced packaging lithography systems.

In MEMS manufacturing — with its complex product mix — mask/reticle overhead costs have a growing impact on CoO, while excellent focus control is critical for patterning in trenches. In the PCB and biomedical markets, demand is growing for a higher degree of pattern flexibility to address a wide range of both feature sizes and substrate sizes.

MLE technology detail

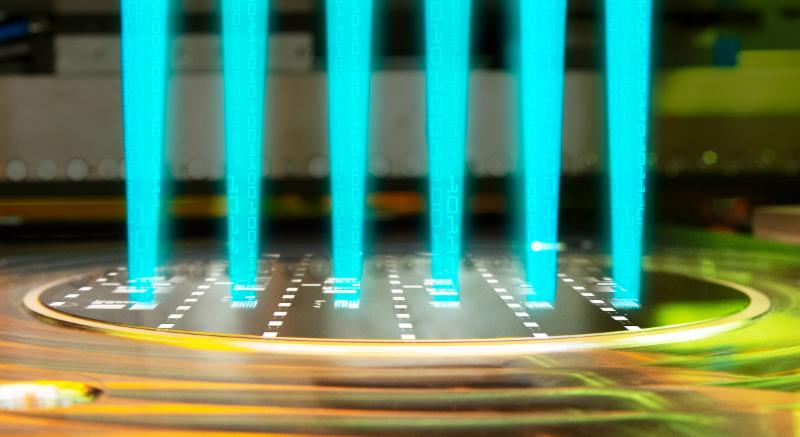

EVG’s MLE technology enables high-resolution (<2 microns L/S), stitch-free maskless exposure of the entire substrate surface with high throughput and low CoO. The system scales according to user needs by adding or removing UV exposure heads — for facilitating rapid transition from R&D to HVM mode, for throughput optimization, or for adaptation to different substrate sizes and materials — and is ideal for processing a range of substrates from small silicon or compound semiconductor wafers up to panel sizes. MLE achieves the same patterning performance regardless of photoresist thanks to a flexible and scalable high-power UV laser source, which provides multiple wavelength exposure options.

“MLE achieves the same patterning performance regardless of photoresist.”

This is impossible to believe. A low-cost resist vs. a high-performance resist will have different results always.

“high throughput and low CoO” … “is ideal for processing a range of substrates from small silicon or compound semiconductor wafers up to panel sizes.”

The more flexible or over-engineered the system is, the more it costs. If it can run both panel and 4″ GaAs wafers then it is not optimized to be cost effective for either.

“MLE achieves the same patterning performance regardless of photoresist”

This is impossible to believe. A low-cost vs. a high-performance resist will always have different results.

“high throughput and low CoO” … “is ideal for processing a range of substrates from small silicon or compound semiconductor wafers up to panel sizes”

If the tool is over-engineered then it is not cost-effective. If a tool can expose both 4″ wafers and large panels then it is not optimized for either.