The use of wearable electronics that continuously monitor biosignals has transformed the healthcare and fitness industries. These devices are becoming increasingly common and are projected to reach a market valuation of approximately USD 572.06 billion by 2033. With this rapid growth, there is an escalating demand for high-quality bioelectrodes capable of accurately recording biosignals over extended periods. However, many of the materials currently used for bioelectrodes, such as metals, conductive polymers, and hydrogels, have limitations. They often lack the flexibility to stretch the skin without breaking and have low humidity permeability, leading to sweat buildup and discomfort.

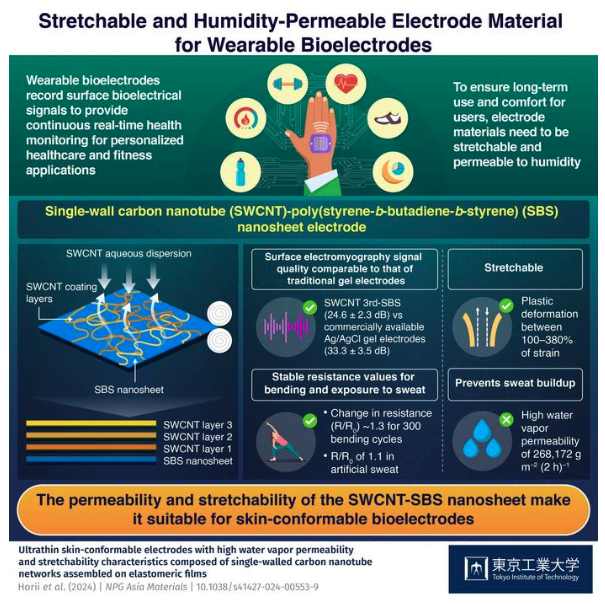

To address these limitations, in a study published in the journal NPG Asia Materials on 20 June 2024, a research team led by Assistant Professor Tatsuhiro Horii and Associate Professor Toshinori Fujie from Tokyo Institute of Technology (Tokyo Tech) has developed a bioelectrode material that is stretchable and permeable to humidity and conforms closely to the skin. This innovative material is composed of layers of conductive fibrous networks consisting of single-wall carbon nanotubes (SWCNTs) on a stretchable poly(styrene-b-butadiene-b-styrene) (SBS) nanosheet. The nanosheet conforms tightly to the skin, allowing for precise biosignal measurements, while the carbon nanotube fibers maintain the material’s stretchability and humidity permeability.

“Self-supporting electrodes that are stretchable, permeable to humidity, and conformable to skin surface bumps are required to allow for the natural deformation of skin without restricting body movements,” says Horii.

The researchers applied SWCNTs as aqueous dispersions onto SBS nanosheets, creating multiple layers reaching a thickness of only 431 nm. Each coating of SWCNTs increased the density and thickness of the fibers, modifying the bioelectrode’s characteristics. While adding more SWCNT layers increased nanosheet stiffness (from an initial 48.5 MPa elastic modulus to 60.8 MPa for a single layer and 104.2 MPa for five layers), the bioelectrode maintained impressive flexibility. Pristine SBS nanosheets and those with one or three layers of SWCNTs (SWCNT 3rd-SBS) stretched elastically by 380% of their original length before permanent deformation. This flexibility surpasses metal electrodes like gold, which have Young’s moduli in the several-hundred-GPa range and can only stretch less than 30% of their original length before breaking.

Another crucial requirement for bioelectrodes is high water vapor permeability to prevent sweat buildup during exercise. Adding SWCNTs is beneficial as its fibrous network structure improves breathability compared to continuous films. In experiments measuring water vapor transmission rate (WVTR), researchers found that SWCNT 3rd-SBS exhibited a WVTR of 28,316 g m-2 (2 h)-1, which is twice that of normal skin.

The bioelectrode material is also highly resilient for extended use. To test the material’s durability, the researchers immersed the bioelectrodes in artificial sweat and subjected them to repeated bending, measuring the change in resistance. In these tests, they found that the resistance increased negligibly, by only 1.1 times in sweat and by 1.3 times over 300 cycles of bending. Furthermore, the SWCNT 3rd-SBS nanosheets showed little to no detachment after being rubbed ten times, indicating its suitability for prolonged use.

To assess its real-world performance, the researchers compared an SBS nanosheet with three layers of SWCNT to commercially available bioelectrode materials such as Ag/AgCl gel electrodes. The bioelectrodes were attached to the forearm, and surface electromyography (sEMG) measurements were taken during gripping motions. In this experiment, the performance of the SWCNT-SBS nanosheet was comparable to that of commercial Ag/AgCl gel electrodes, achieving similar signal-to-noise ratios of 24.6 dB and 33.3 dB, respectively.

“We obtained skin-conformable bioelectrodes with high water vapor permeabilities, which showed comparable performance in sEMG measurements to those of conventional electrodes,” concludes Fujie, highlighting the material’s promising capabilities for healthcare wearables.