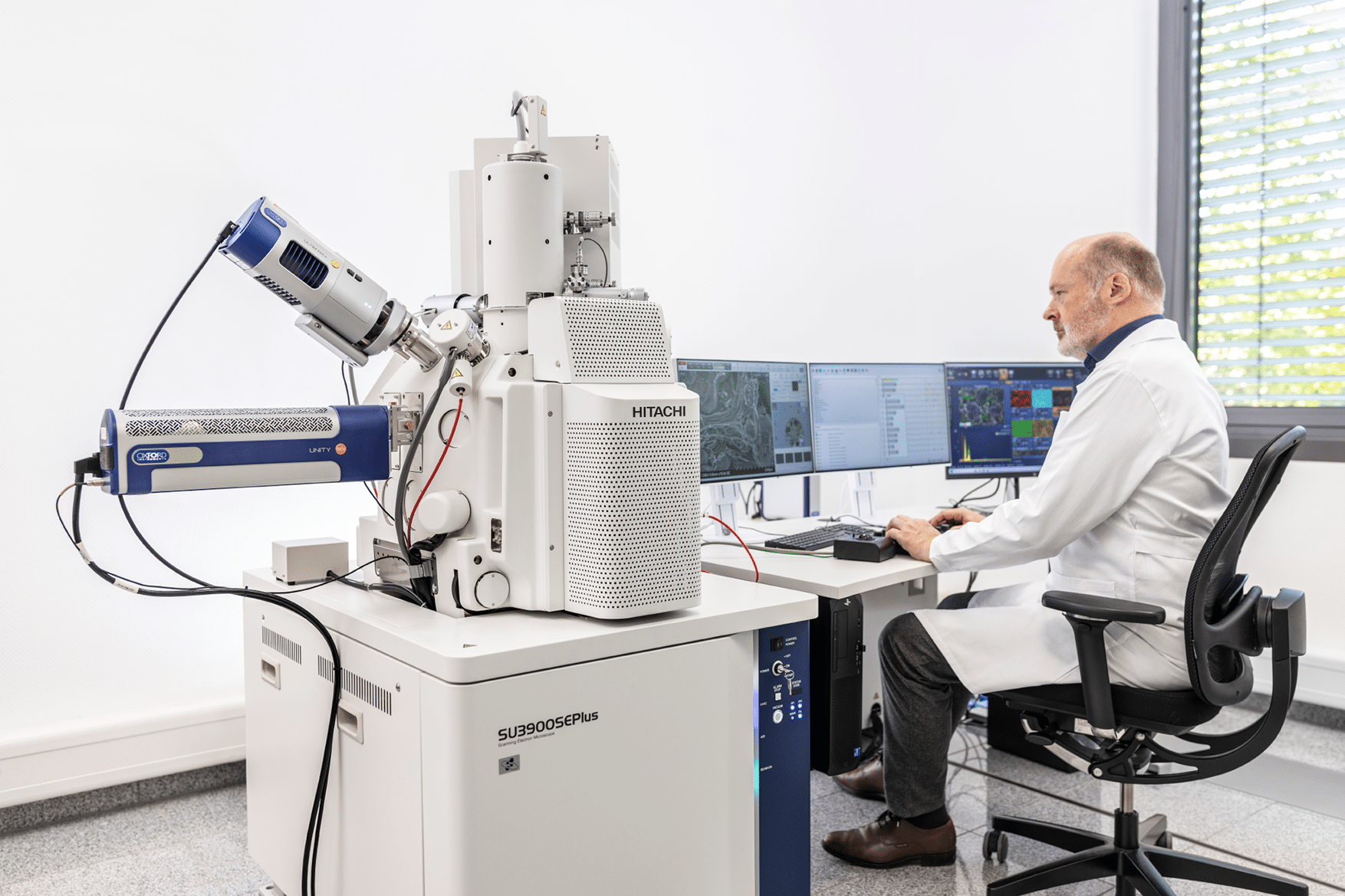

Hitachi High-Tech Europe has introduced the SU3800SE and SU3900SE Schottky field emission scanning electron microscopes (SEMs) to offer fully automatic optical alignment, allowing high-resolution results to be achieved quickly and easily by any user. The large sample handling and variable pressure operation means they can accommodate a wide range of sample types, and the powerful automation tools enable easy acquisition of large datasets.

The SU3800SE and SU3900SE sit alongside the tungsten emitter versions of this modular platform (SU3800 and SU3900) offering the same field-proven sample handling and automation capabilities. The new Schottky field emission versions offer higher resolution imaging, enhanced low voltage performance, and even greater ease of use.

A wide range of sample sizes

The SU3900SE offers a robust, fully eucentric stage capable of holding specimens up to 300 mm in diameter and 130 mm in height, with a maximum loadable weight of 5 kg. It is ideal for imaging large or heavy materials like automotive components, PCBs, or precious samples which can’t be cut down to smaller sizes. The SU3800SE accommodates specimens up to 200 mm in diameter, 80 mm in height, and 2 kg in weight.

Easy navigation and precision control

Both models feature an advanced navigation system that uses optical cameras to cover the entire range of motion of the specimen stage. This functionality helps users locate specific areas of interest quickly. Also, the system allows the camera to follow the stage’s rotation, providing accurate real-time feedback on specimen positioning.

Automated workflows free time and enable bigger datasets

The SU3800SE and SU3900SE support the optional EM Flow Creator function, which enables fully automated operation. EM Flow Creator’s powerful building-block methodology enables even complex workflows to be created with simple drag-and-drop flowchart creation, and without the need for script writing. Users can define and control almost all aspects of microscope operation and include pre-written modules like feature centering for “intelligent” automatic acquisition. Easy automation is ideal for users handling high-throughput tasks, ensuring consistent data quality and faster time to data.

High-resolution and auto-aligned imaging for consistent, high-quality images

The SU3800SE and SU3900SE offer superior image quality for any user, even at very high resolutions thanks to fully automatic optical alignment and sensitive detector systems. Minimal training is needed to obtain high-quality images, so even inexperienced users can get excellent results quickly. Time to data is fast and the results are easily interpretable, reducing the time needed to perform and analyse results.

Users can also tailor the new models to suit their analytical needs with a range of optional extras. These include Hitachi Map 3D, which enables 3D surface reconstruction and roughness measurement, a sample exchange chamber for vacuum transfer of specimens, and analysis accessories such as EDX and EBSD.

Kazuyoshi Matsukaze, President of Hitachi High-Tech Europe GmbH, commented: “The new SEMs in our portfolio provide an innovative solution for both industrial and academic applications. The ability to accommodate large or heavy specimens in the SU3900SE makes this SEM ideal for quality control in industries like automotive, aerospace, and materials science, or in environments where precious specimens cannot be cut down. High resolution imaging and powerful chemical analysis can be performed for a wide variety of samples, with lower user training requirements.”