In the rapidly evolving world of semiconductors, chiplet technology is emerging as a groundbreaking approach that addresses many of the challenges faced by traditional monolithic System-on-Chip (SoC) designs, as outlined in the new report, “Chiplet Technology 2025-2035: Technology, Opportunities, Applications,” from market intelligence firm IDTechEx. As Moore’s Law slows down, the semiconductor industry is seeking innovative solutions to increase performance and functionality without merely increasing transistor density. The report highlights how chiplets offer a promising path forward, providing flexibility, modularity, customizability, efficiency, and cost-effectiveness in chip design and manufacturing.

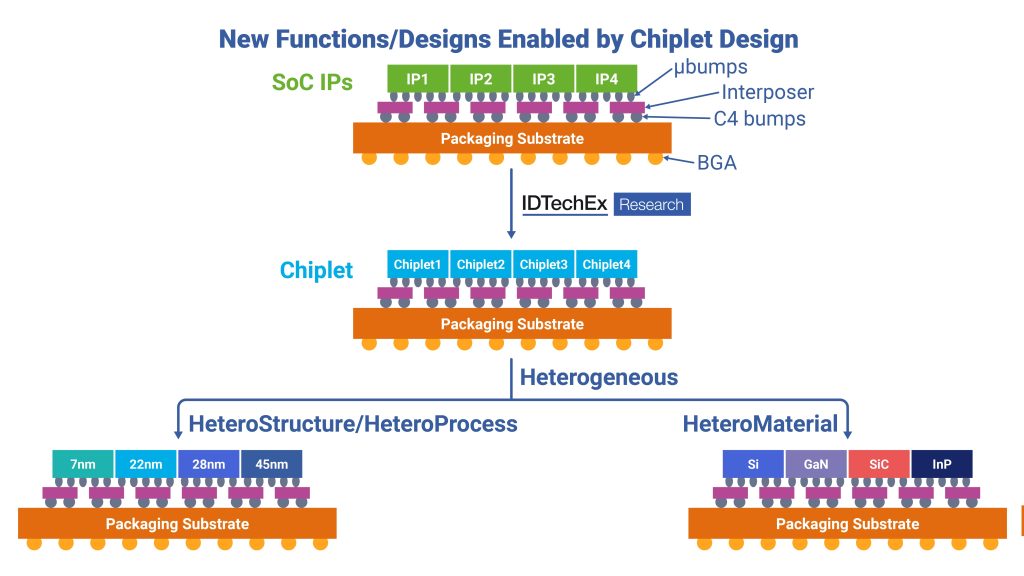

Dr. Xiaoxi He, IDTechEx Research Director and co-author of the report, explains that chiplets are discrete modular semiconductor components that are co-designed and manufactured separately before being integrated into a larger system. This approach resembles an SoC on a module, where each chiplet is designed to function in conjunction with others, necessitating co-optimization in design. The modularity of chiplets aligns with key semiconductor trends such as IP chipletization, integration heterogeneity, and I/O incrementalization. Chiplet is also associated with heterogeneous integration and advanced packaging.

Dr. He advises, “The global market for chiplets is experiencing remarkable growth, driven by high-performance computing demands across sectors, such as data centers and AI, and is projected to reach US $411 billion by 2035. The modular nature of chiplets allows for rapid innovation and customization, catering to specific market needs while reducing development timelines and costs.”

Dr. He continues, however, “While chiplets offer numerous advantages, they also present new challenges. The integration of multiple chiplets requires advanced interconnection technologies and standards to ensure seamless communication between components. Thermal management is another critical area, as increased function density can lead to overheating if not properly managed.”

These challenges open up opportunities for various players in the supply chain. For instance, different areas of the package in chiplet design require distinct types of underfill materials to address specific needs, e.g. to protect the chips themselves, providing mechanical support and thermal stability, as well as to safeguard the delicate wires and solder balls that connect the chiplets, preventing issues such as delamination or separation. This creates demand for innovative materials that enhance reliability and performance.

“Chiplet Technology 2025-2035: Technology, Opportunities, Applications” provides a comprehensive analysis of the chiplet technology landscape, exploring the drivers and benefits that make chiplet design attractive and identifying the challenges and hurdles in its adoption and implementation. It provides insights into technology and manufacturing processes, including design methodologies and packaging techniques. For more information, please visit www.IDTechEx.com/Chiplet.