Declan Scanlan and Dawn Stephenson, Semiconductor Division, Edwards Vacuum, San Jose, CA

As device lateral dimensions continue to shrink at each technology node, the semiconductor industry is now poised to transition from the nanoscale era to the atomic scale era. This will require the broader adoption of atomic scale processing techniques like atomic layer deposition (ALD) and atomic layer etching (ALE). Atomic layer processes use a repetitive cycle of self-limiting reactions in which the first step prepares a monatomic layer at the surface and the second step either completes the deposition or removes the prepared layer. Although atomic layer processes provide very precise control, their adoption has been slowed by productivity limitations. Throughput of atomic layer processes is largely driven by the need for the reactive gases in the process chamber to be completely exchanged between each step in the repeated cycle. Any technology that accelerates this exchange will directly improve throughput and productivity. To this end, process equipment manufacturers have developed novel fast gas delivery hardware, but the complementary rapid gas evacuation capability has received less attention.

Apart from this extended pumping time requirement, these high-flow steps present other productivity challenges to the vacuum system. Historically, the chamber vacuum systems have used turbomolecular pumps (TMPs) to deliver low pressure. These pumps operate by spinning bladed rotors at very high speeds to propel gas molecules through and out of the pump exhaust. In general, the higher the gas flow rate, the more heat that is imparted to the TMP rotor and the higher the resulting rotor temperature. The internal pump temperature profile must be kept high enough to prevent accumulation of condensable process gases and by-products on surfaces in the gas path. At the same time, temperatures that are too high can cause rotor material creep (permanent deformation) and promote corrosion. Provision must also be made to avoid mixing of gases from different phases of the process cycle, which could lead to deposition or etching (in-situ ALD/ALE) within the vacuum system. Finally, these processes are very sensitive to defectivity caused by particles.

New materials

Advanced etch processes have introduced a variety of new materials. The primary concerns for the vacuum system are the prevention of corrosion and condensation. Both are influenced by the temperature profile of the pump, though in opposing directions – lower temperatures inhibit corrosion while higher temperatures inhibit condensation.

Atomic layer etch of silicon begins with the adsorption of a monolayer of chlorine on the silicon surface, weakening the bonds between the topmost silicon atoms and the underlying silicon substrate. The chlorine, a corrosive gas, is then removed from the chamber and the surface is bombarded by Ar+ ions from a plasma. The ions have just enough energy to remove the monolayer of chlorinated silicon atoms, which are then pumped out of the chamber by the vacuum system, but not the underlying, tightly bonded silicon atoms of the bulk substrate.

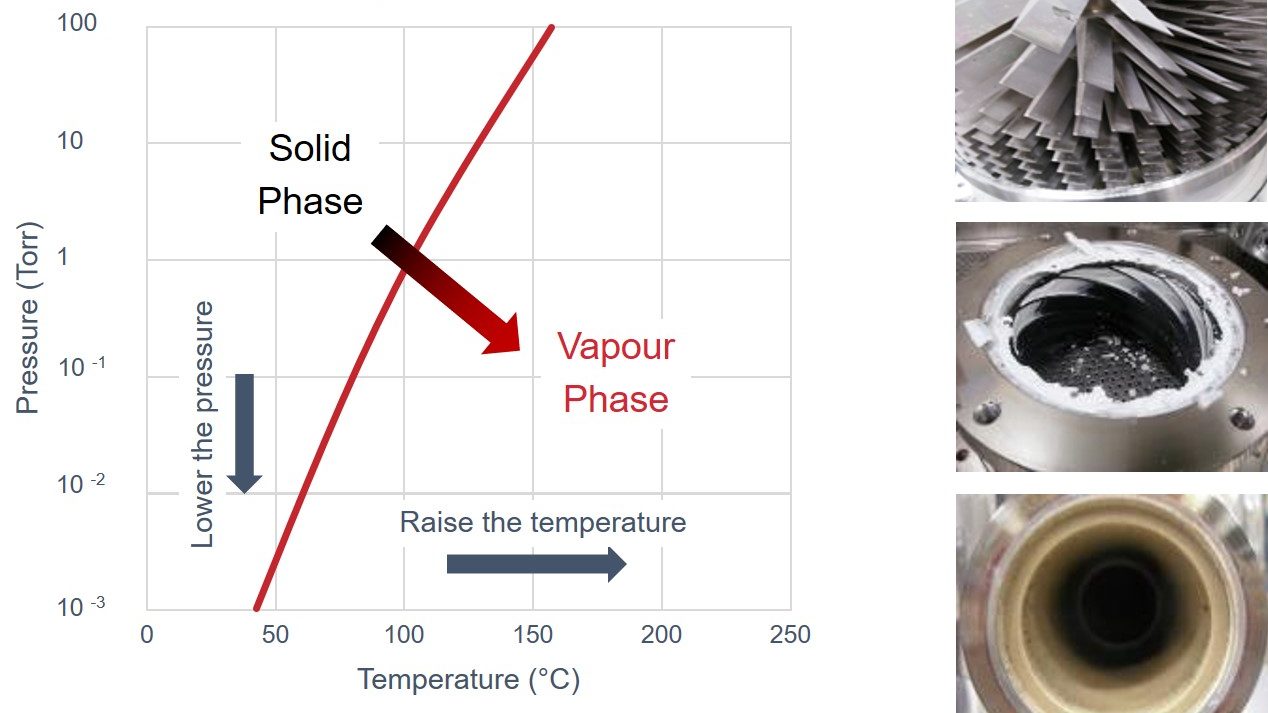

Figure 1 shows the phase diagram for AlCl3; one potential by-product of atomic layer processing. In order to avoid deposition on pump surfaces, the temperature and pressure of the gas must remain to the right and below the vapor/pressure curve – at lower pressures and higher temperatures. Temperature can be controlled by careful design of the pump and pressure (partial pressure) by optimal design, reactant gas flowrates or dilution with a non-condensable gas. The images in Figure 1 show the deposits that can occur on pump surfaces when condensation is not managed appropriately. Deposition of condensable gases will eventually cause the pump to fail.

High flows

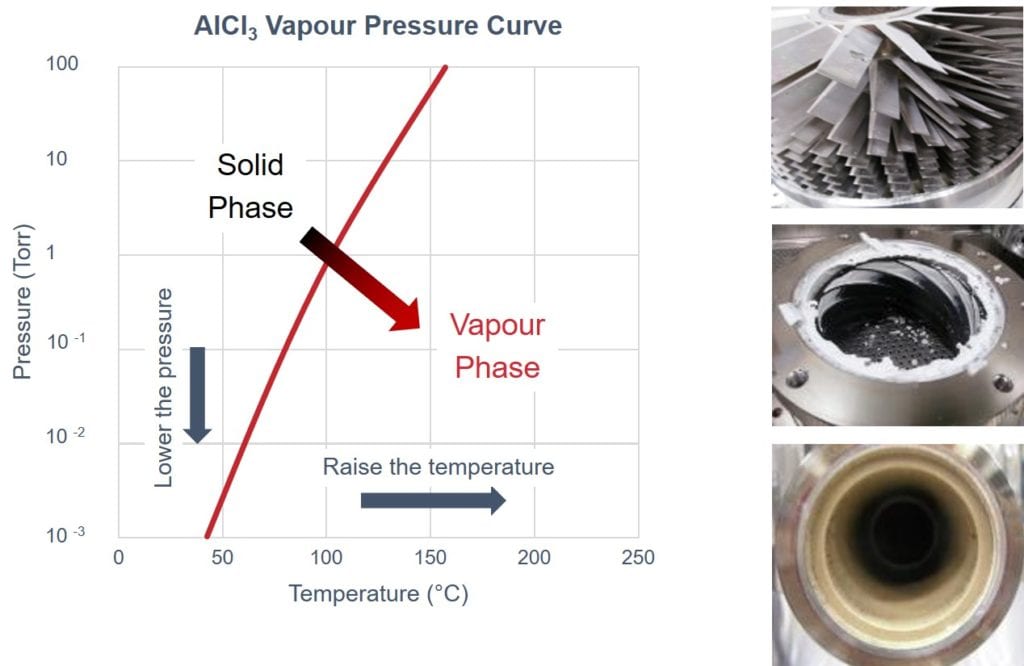

High gas flow rates required by atomic layer processes pose another thermal challenge for turbomolecular pumps. At high flow rates, the gas imparts more heat energy to the rotor. Because it is operating in a vacuum environment with no physical contact to the pump body, the primary mechanism for heat loss of a magnetically levitated rotor is by radiation. As its temperature rises, the rotor material expands, and the rotor deforms. When the rotor sustains very high temperature and centrifugal stress over a long period of time, rotor creep can occur; permanent deformation/growth in radial direction. Figure 2 plots creep as a function of time at various temperatures. Given the very tight clearances of the rotors, excessive creep will ultimately lead to pump catastrophic failure.

Two features have been developed for turbo pumps to enable high flow applications. A corrosion resistant, black ceramic rotor coating maximizes radiative heat loss and helps keep the rotor cool. Direct, dynamic rotor temperature reporting allows pump operation at real maximum gas flows without risking deformation related damage.

Faster cycling

Atomic layer etch provides the tight control required to create very high aspect ratio features, but it may have to complete hundreds of cycles to deliver the required results. While cycle times have been reduced from minutes to seconds, further reductions are very valuable, especially when they are achieved by eliminating the “dead time” needed to exchange gases in the process chamber.

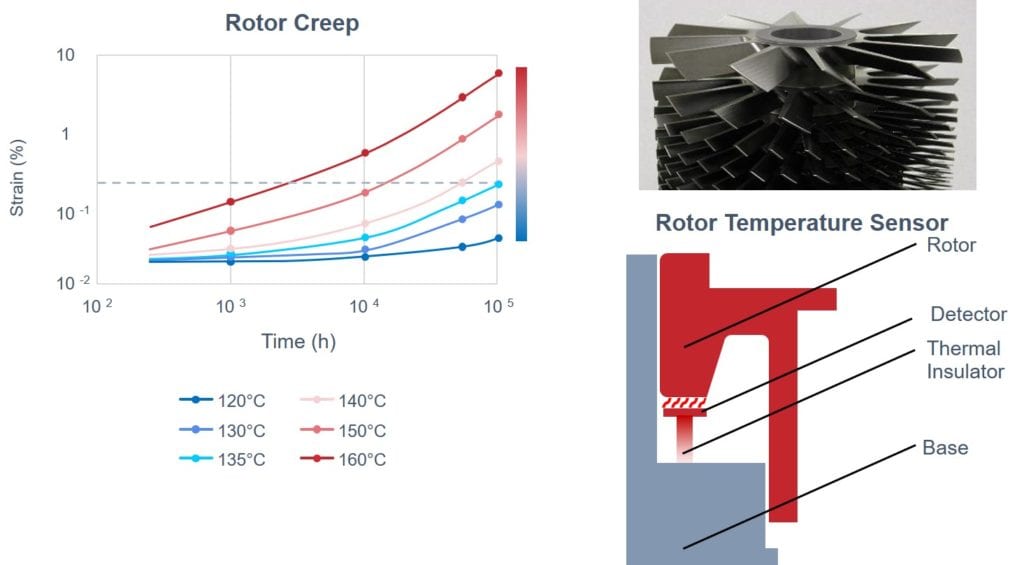

Turbo pumps operate most efficiently at low pressures where the mean free path of gas molecules is larger than the average distance between collisions with the rotor and stator blades. Under these conditions the gas is in the molecular flow regime and the gas molecule will most likely be propelled toward the pump outlet by successive collisions with the rotor and stator blades. When the pressure rises, collisions with other gas molecules become more likely and the efficiency of the pump degrades. Compound turbo pumps include a drag stage below the turbine blade stage, designed to pump more efficiently at higher pressures. A compound turbo pump can somewhat extend the effective pumping speed into the transitional flow regime. However, under higher pressure, pumping speed in the viscous flow regime is most efficient with the standard dry pump (Figure 3).

The productivity demands of atomic scale processing, especially in relation to the gas exchange requirements discussed above, ultimately dictate that pumping speed must be maximized across a wide range of pressure and flow regimes. With some desirable process conditions for both ALD and ALE falling within the crossover transitional flow regime, this particular area is the focus of current development work.

Defectivity

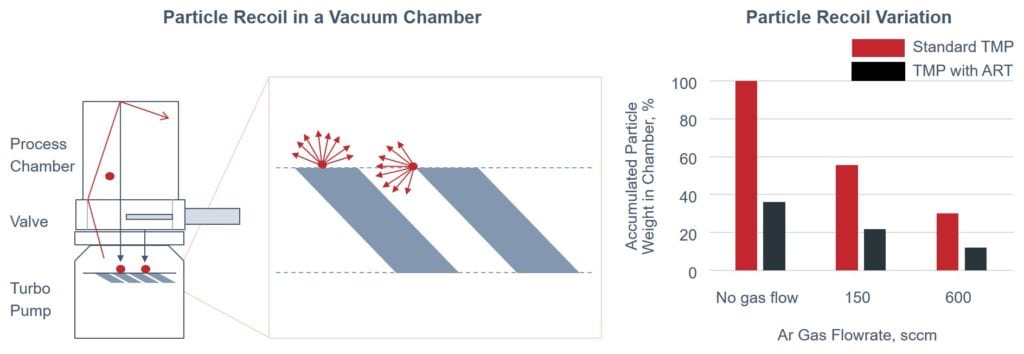

Yield losses from particulate contamination may be amplified in the presence of high aspect ratio features, which are especially good at trapping and hiding particles. The defect does not become apparent until testing and after considerable additional processing investment. Turbo pumps may capture particles and remove them with exhaust gases or reflect them back into the process chamber. Conventional approaches to preventing particle recoil typically rely on some form of screening device over the pump inlet, but these unavoidably reduce pumping speed and efficiency. Anti-recoil technology (ART) reduces the number of particles deflected back into the process chamber, without compromising the effective pumping speed. Figure 4 shows the results of an experiment that compares the number (weight) of particles reflected into the chamber with and without ART at various flow rates.

Conclusion

As further shrinks in planar devices have become more difficult, semiconductor manufacturers have gone vertical in their efforts to continue to pack more processing power into less space. The structures they have created include many high aspect ratio features, and the processes they use to build these features present a variety of challenges to the chamber vacuum systems. These processes include atomic layer deposition and etch, which require fast, repetitive, complete exchange of gases in the process chamber. Vacuum equipment manufacturers have reponded with solutions that address the challenges presented by these high flow applications. These include thermal management to prevent deposition of condensable gases on pump surfaces, coatings and sensors to reduce heat-induced rotor deformation, careful design of pumping elements that match flow regimes to reduce gas exchange times, and anti-recoil technology to reduce particulate contamination. Together, these technologies can make a significant contributions to improving speed and efficiency in high-flow applications.