MANDY GEBHARDT, scia Systems

Mobile communication technology has revolutionized how we connect, interact, and conduct business. At the heart of this revolution are frequency filters. These critical components ensure signals’ proper transmission and reception by isolating specific frequency bands to minimize interference and improve signal clarity. High-quality filters ensure better signal clarity, reduce interference, and improve overall network reliability.

Among the advanced techniques used to produce high-quality high-frequency filters, ion beam processing technology stands out due to its precision and efficacy. High-frequency filters in mobile communication incorporate many layers of thin films composed of various materials. The uniformity requirements for each film layer are very high. The application of ion beam processing technology for trimming these films to the required dimensions can significantly enhance the performance of mobile communication systems.

Ion beam etching overview

Ion beam etching (IBE) – also known as ion beam milling (IBM) – is ideally suited for precise surface processing. The technology uses a directed beam of high-energy ions to selectively remove material from the surface and create specific patterns or structures. The ion beam process combines physical and chemical etching. Physical etching uses the kinetic energy of fast inert ions bombarding the surface to sputter, releasing atoms from the target surface. That process works on all materials facing the ion beam. Chemical etching utilizes a chemical reaction between the reactive ions and the target surface. The reaction products must, therefore, be volatile.

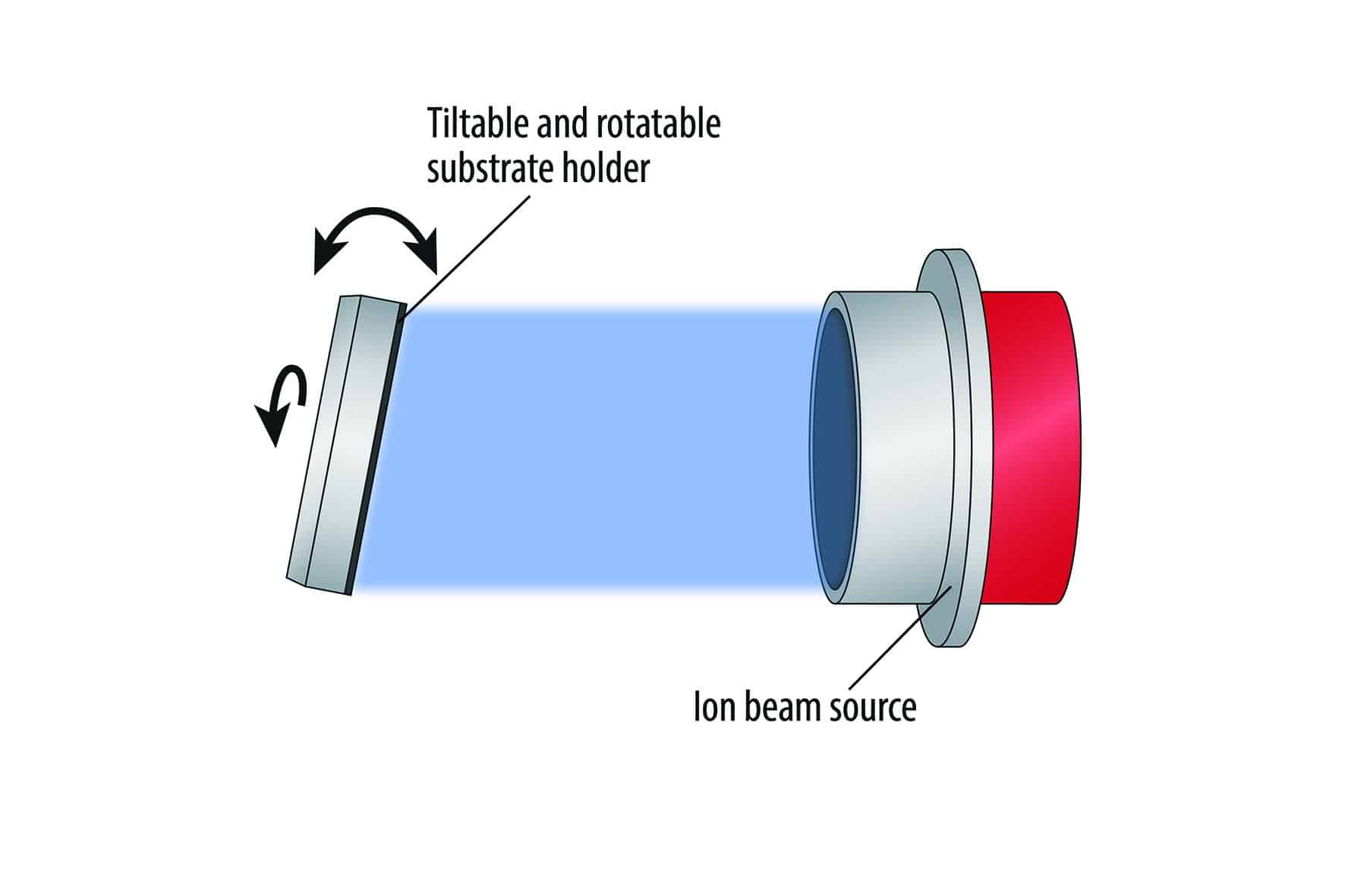

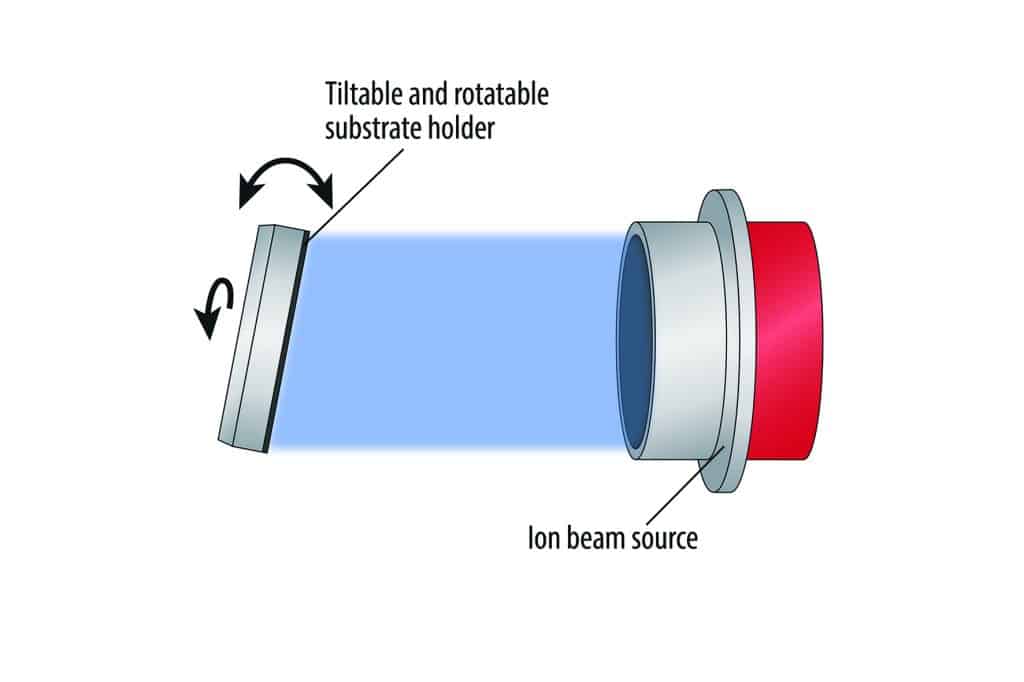

A broad beam of positively charged ions, typically argon ions, is accelerated onto a substrate (FIGURE 1). The ions transfer their kinetic energy to the surface atoms, causing them to be ejected, thus removing the material. The ion beam is typically larger in diameter than the substrate size. That ensures sufficient removal uniformity and throughput. During milling, the wafer substrate can rotate for the best uniformity. Chemically reactive gases can be added to enhance the etch rate.

By varying the angle of incidence and the substrate rotation, material removal can be adjusted precisely to achieve a perfect etching structure with superior homogeneity. This allows for the creation of many different geometries in a wide spectrum of processable materials.

Read the full article in the October issue of Semiconductor Digest.