Hydrogen gas and methanol for fuel cells or as raw materials for the chemicals industry, for example, could be produced more sustainably using sunlight, a new Uppsala University study shows. In this study, researchers have developed a new coating material for semiconductors that may create new opportunities to produce fuels in processes that combine direct sunlight with electricity. The study is published in Nature Communications.

“We’ve moved a step closer to our goal of producing the fuel of the future from sunlight,” says Sascha Ott, Professor at the Department of Chemistry, Uppsala University.

Today, hydrogen gas and methanol are produced mainly from fossil sources like oil or natural gas. An environmentally sounder, climate-friendlier option is to make these substances from water and carbon dioxide, using sustainable electricity, in what are known as electrolysers. This process requires electrical energy in the form of applied voltage.

The scientists have devised a new material that reduces the voltage needed in the process by using sunlight to supplement the electricity.

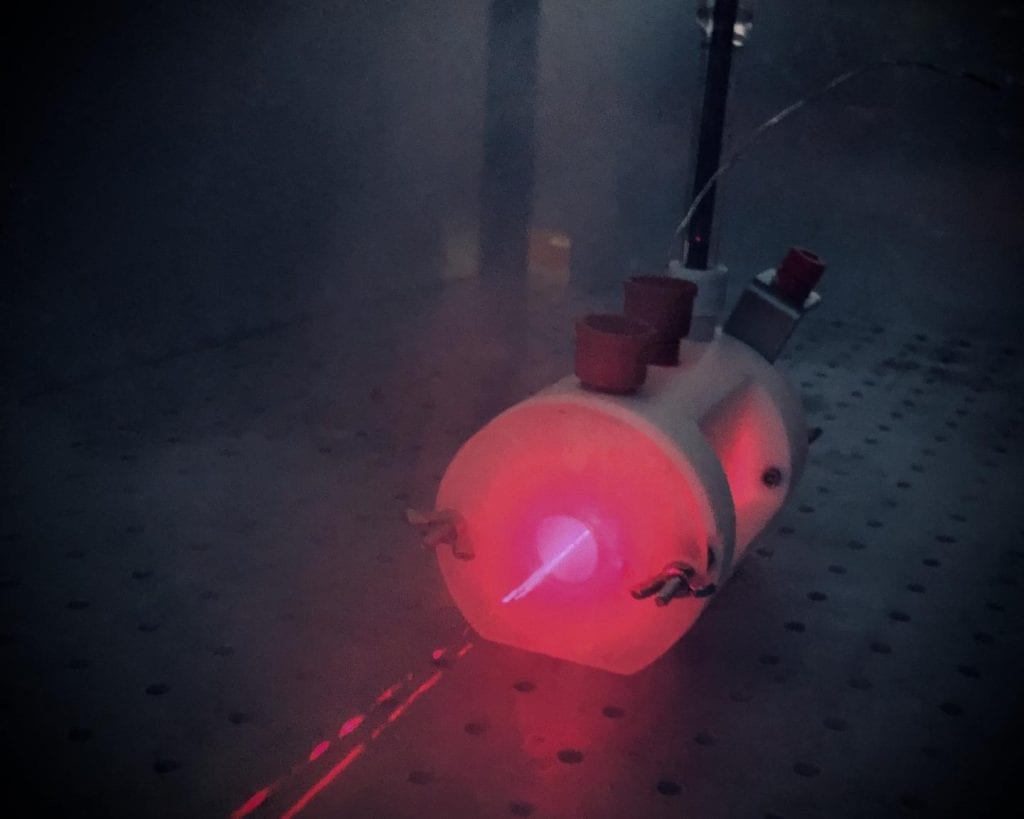

To capture the sunlight, they used semiconductors of the same type as those found in solar cells. The novel aspect of the study is that the semiconductors were covered with a new coating material that extracts electrons from the semiconductor when the sun is shining. These electrons are then available for fuel-forming reactions, such as production of hydrogen gas.

The coating is a “metal-organic framework” – a three-dimensional network composed of individual organic molecules that are held in place, on the sub-nanometre scale, by tiny metal connectors. The molecules capture the electrons generated by the sunlight and remove them from the semiconductor surface, where undesired chemical reactions might otherwise take place. In other words, the coating prevents the system from short-circuiting, which in turn allows efficient collection of electrons.

In tests, the researchers were able to show that their new design greatly reduces the voltage required to extract electrons from the semiconductor.

“Our results suggest that the innovative coatings can be used to improve semiconductor performance, leading to more energy-efficient generation of fuels with lower electrical input requirements,” Sascha Ott says.