Real-time health monitoring and sensing abilities of robots require soft electronics, but a challenge of using such materials lie in their reliability. Unlike rigid devices, being elastic and pliable makes their performance less repeatable. The variation in reliability is known as hysteresis.

Guided by the theory of contact mechanics, a team of researchers from the National University of Singapore (NUS) came up with a new sensor material that has significantly less hysteresis. This ability enables more accurate wearable health technology and robotic sensing.

The research team, led by Assistant Professor Benjamin Tee from the Institute for Health Innovation & Technology at NUS, published their results in the prestigious journal Proceedings of the National Academy of Sciences on 28 September 2020.

High sensitivity, low hysteresis pressure sensor

When soft materials are used as compressive sensors, they usually face severe hysteresis issues. The soft sensor’s material properties can change in between repeated touches, which affects the reliability of the data. This makes it challenging to get accurate readouts every time, limiting the sensors’ possible applications.

The NUS team’s breakthrough is the invention of a material which has high sensitivity, but with an almost hysteresis-free performance. They developed a process to crack metal thin films into desirable ring-shaped patterns on a flexible material called polydimethylsiloxane (PDMS).

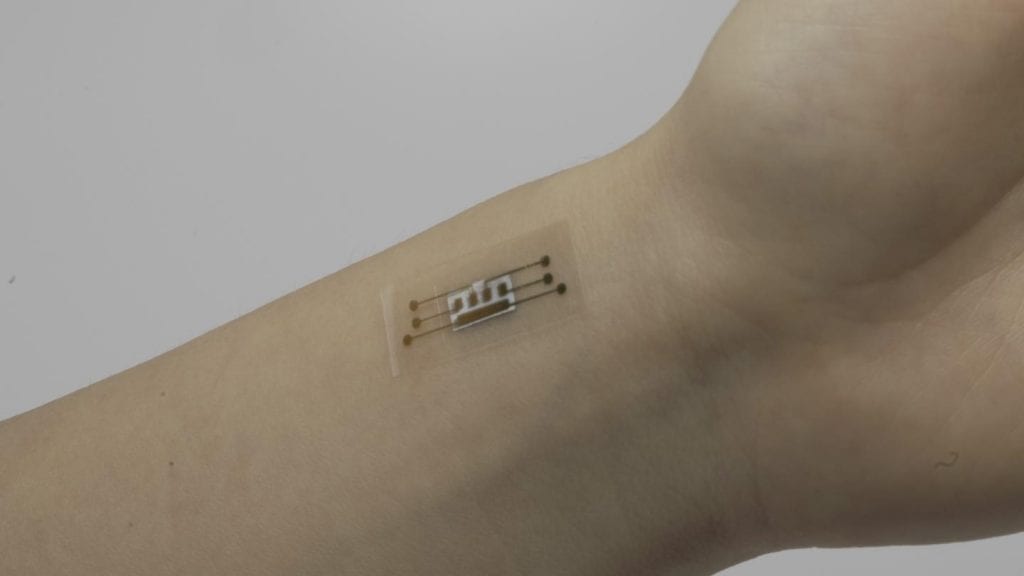

The team integrated this metal/PDMS film with electrodes and substrates for a piezoresistive sensor and characterised its performance. They conducted repeated mechanical testing, and verified that their design innovation improved sensor performance. Their invention, named Tactile Resistive Annularly Cracked E-Skin, or TRACE, is five times better than conventional soft materials.

“With our unique design, we were able to achieve significantly improved accuracy and reliability. The TRACE sensor could potentially could be used in robotics to perceive surface texture or in wearable health technology devices, for example to measure blood flow in superficial arteries for health monitoring applications” said Asst Prof Tee, who is also from the NUS Department of Materials Science and Engineering.

Next steps

The next step for the NUS team is to further improve the conformability of their material for different wearable applications, and to develop artificial intelligence (AI) applications based on the sensors.

“Our long-term goal is to predict cardiovascular health in the form of a tiny smart patch that is placed on human skin. This TRACE sensor is a step forward towards that reality because the data it can capture for pulse velocities is more accurate, and can also be equipped with machine learning algorithms to predict surface textures more accurately,” explained Asst Prof Tee.

Other applications the NUS team aims to develop include uses in prosthetics, where having a reliable skin interface allows for a more intelligent response.