Chipmakers have long selected manufacturing equipment that mitigates risk, choosing tools that are the most reliable, produce the best throughput, have the best uptime and, of course, do what they’re supposed to do, whether it’s etching, deposition, cleaning, polishing, annealing, etc.

Now, that same strategy is being applied to the service side as well. “Service is starting to come into that risk mitigation category,” said Alex Smith, Vice President of Marketing, Semiconductor Service at Edwards. “They’re finding that service isn’t just about fixing broken parts; it’s about ensuring the entire system operates optimally, which minimizes risk. Service is greater than sum of the parts.”

Smith said that, in the past, semiconductor manufacturers employed what he calls a “break-fix” model where products such as vacuum pumps are run until they break and then replaced. The trouble is that it’s the most expensive approach, which only gets worse as capacity expands. “If your service regime is too cheap, you’re absolutely taking risks,” he said. “You’re taking large risks because it results in unreliable equipment that has poor uptime. It really makes it difficult to optimize the efficiency of the fab. It drives higher total cost of ownership, and it absolutely impacts fab utilization.”

Smith said Edwards has done a lot of work to understand what the overall service costs are. “Obviously, you pay for parts and whatever the service level you have. But then you’ve got the cost of unplanned down times, the cost of wafer scraps and the cost of re-qualifying tools and processes. Those costs are absolutely huge,” he said. “It’s not until you fully see and understand those costs that you realize the pure price you pay for servicing is actually quite a small part of what the overall cost is in terms of the maintenance and the service of the equipment.”

Smith said the best approach to servicing is to use data-driven solutions for decision making, including data from the subfab where equipment such as vacuum pumps and gas abatements systems are located.

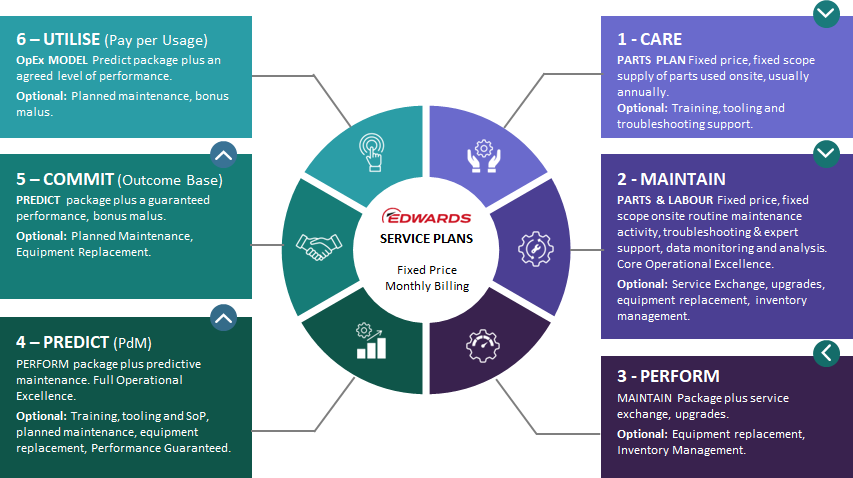

Last year, Edwards launched its Semiconductor Intelligent Service, an offering of services created to enhance the customer experience, with a focus on providing tailored service plans that align with the specific needs and goals of each customer.

Edwards’ services range from transactional to proactive service and risk management plans utilizing predictive maintenance technology. They have been created to minimize the total cost of ownership and environmental impact, while optimizing customer productivity (see Figure).

“We absolutely want to co-own and co-manage the risk with customers. We want to be part of that productivity. That’s where the value is really in servicing the whole entire system, from the dry pumps and abatement systems right up into the cleanroom. It all becomes part of a much more holistic risk mitigation service plan.”