SABIC introduced its new high-purity SD1100P specialty dianhydride powder for polyimide (PI) film formulations for potential use in 5G flexible printed circuit boards (PCBs), colorless displays and other flexible electronics applications. This 4,4’-bisphenol A dianhydride (BPADA) powder helps customers produce high molecular weight PI formulations that can deliver improved balance between thermal and mechanical properties. Compared to other commercially available dianhydrides, SABIC’s SD1100P BPADA powder may offer performance improvements including a lower dielectric constant and dissipation factor, reduced water absorption and improved metal adhesion for creating films and varnishes used in copper-clad laminates, coverlays and adhesives.

“Reaching the full potential of 5G networking requires next-generation electronics solutions such as flexible PCBs that can deliver higher performance in ever-smaller and thinner packaging,” said Brian Rice, senior business manager, Additives, SABIC. “SABIC is supporting innovations in electronics with advanced material solutions like our new specialty dianhydride powder. Leveraging SABIC’s deep manufacturing expertise, this high-purity monomer can help customers improve film properties to meet demands for higher speed and capacity in 5G networking infrastructure and endpoint devices.”

Enhancing PI Films for Flexible Electronics

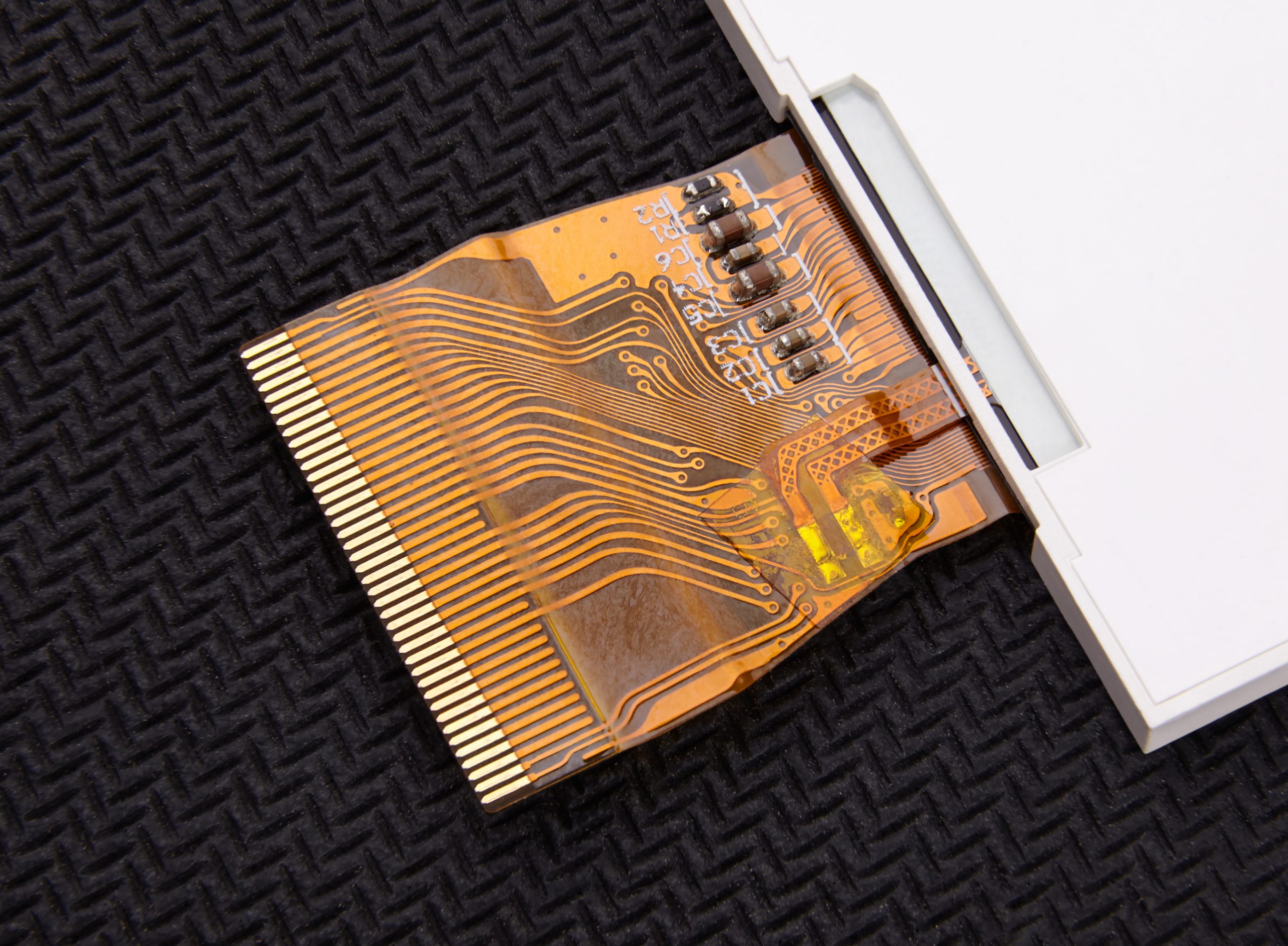

Lightweight, ultra-thin and foldable flexible electronics offer significant potential for new applications, such as curved displays for flexible smartphones and substrates for antennas. According to MarketWatch, the flexible electronics market is forecast to grow at double-digit rates through 2024. Polyimide film is a preferred substrate thanks to its mechanical strength, high temperature resistance, dimensional stability, a coefficient of thermal expansion close to that of copper, and a low dielectric constant.

To enhance PI films, SABIC’s new SD1100P BPADA powder offers superior performance properties versus other types of dianhydrides. For instance, the SABIC product delivers lower water absorption, better dielectric performance and metal adhesion compared to oxydiphthalic anhydride (ODPA). Improving metal adhesion in PCBs not only increases their reliability but also permits the use of thinner, smoother copper, which decreases part size and increases signal transmission performance.

SABIC’s SD1100P dianhydride powder also offers formulators a potential solution that can help reduce the color of PI film for colorless glass display replacements. The new powder improves processability to help PI manufacturers extend the limits of film performance for demanding 5G applications. For example, in PI formulations, the SD1100P powder may improve metal adhesion and processing in thermal lamination processes, reducing the amount of heat, pressure and time required to laminate materials. These features may also support two-layer laminate construction for thinner profile flexible circuits.

“Leveraging our polymer chemistry expertise, SABIC is committed to providing thermoset formulators with new material options to help optimize the performance of emerging applications,” said Dr. Bimal R. Patel, senior manager, Additives Technology, SABIC.

The high-purity SD1100P powder expands SABIC’s growing portfolio of dianhydrides, which also includes the BISDA 1000 product, which may be used in polyimide varnishes and as a curing agent for high-temperature thermoset epoxy systems. More information on the new SD1100P BPADA powder can be found by downloading our new SD1100P Powder Technical Bulletin.

![]()