TECHCET—the electronic materials advisory services firm providing business and technology information—announces that 2020 global materials revenues in semiconductor fabrication are now forecasted upward year-over-year (YoY) despite potential disruptions to manufacturing:

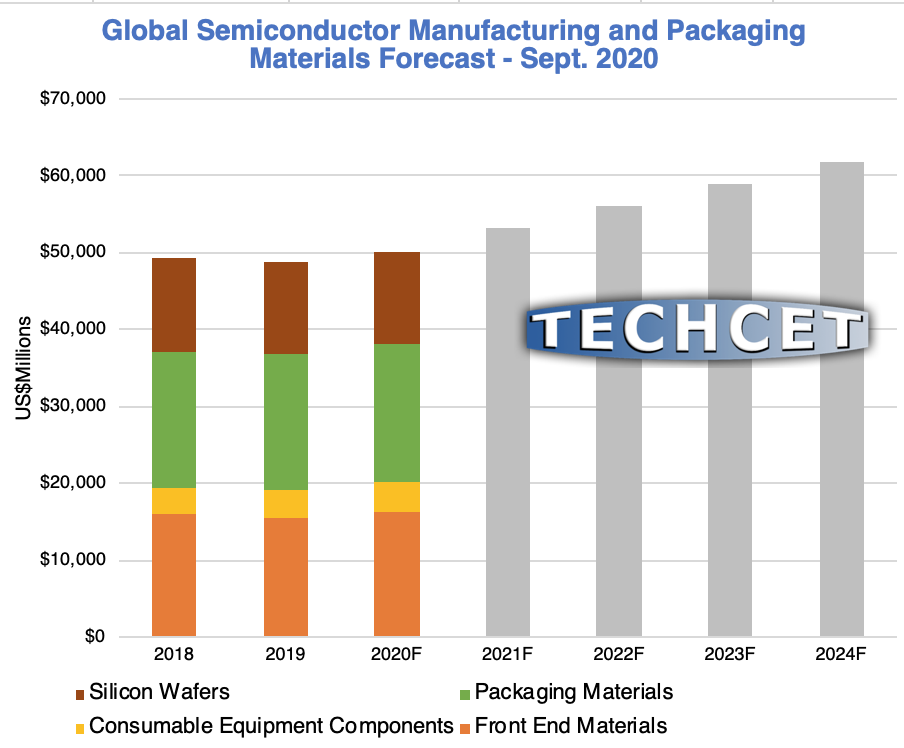

- Overall revenues +2.8% to hit over $50B, versus outlook in April for -3%,

- Front End Materials +5% to hit $16.4B, and

- Equipment Components +10% to hit $3.8B.

While the impact of COVID-19 on the global economy is serious, IC fabrication is steady for devices to Work From Home (WFH) and School From Home (SFH). As predicted, leading-edge ICs to build out data centers are in strong demand this year, as part of forecasted 5.4% Compound Annual Growth Rate (CAGR) for fab materials through the year 2024 (Figure below).

“TECHCET now sees Front-End Materials volumes and revenues for the year 2020 to be buoyed up by cloud computing and devices to support Work From Home and School From Home,” remarked Lita Shon-Roy, TECHCET President and CEO. “In recent online meetings the members of the Critical Materials Council of Semiconductor Fabricators have said that most fabs are running at normal levels, while leading-edge logic and memory fabs are actually having a great year.”

Advanced logic fabrication now drives a massive 30% YoY increase in demand for cobalt (Co) deposition precursors. Because of the need for speed and reliability in the most advanced finFET logic chips, the smallest on-chip wires are being converted to cobalt from copper (Cu). Interconnect metallization for semiconductors continues to grow in general, so demand for copper remains strong albeit somewhat reduced. Sourcing cobalt is still problematic due to conflict-mining in the Democratic Republic of the Congo, yet companies such as Umicore and Australian Mines have gone to great lengths to ensure their sources are conflict-free and sustainable.

Chemical-Mechanical Planarization (CMP) Pad Conditioner revenues for 300mm wafers are growing at 4.5% for 2020, due to 3D-NAND device volume growth and overall equipment sales. CMP processing flattens the surface as device layers are stacked up, and the CMP pad lifetime is increased with corresponding manufacturing cost-reduction by use of specialized diamond-abrasive conditioning disks.

Packaging materials revenues for 2020 should be up >1% due to the relative increase in value of advanced packaging, as more and more chips require interconnects faster than wire-bonds. This is a continuance of the multi-year trend of multi-chip packages using flip-chips and interposers and embedded-bridges. Deep details on packaging materials can be found in the “Global Semiconductor Packaging Materials Outlook” report published by SEMI, TECHCET, and TechSearch, available at the SEMI website.