By Alan Ifould

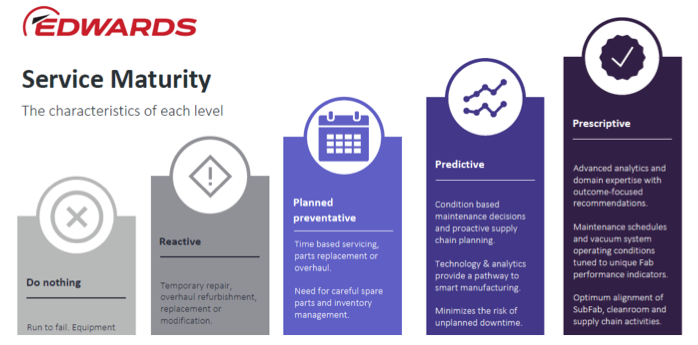

In our last post to this blog, we described Edwards’ service maturity model*, which establishes a framework for understanding the service and support approaches most appropriate for customers based on their position within an evolutionary hierarchy that goes from run-to-fail to preventative, predictive, and, ultimately, prescriptive maintenance models. As customers move up the hierarchy, service and maintenance activities transform from a non-productive cost, to be minimized and avoided, to a cost-reducing, value-adding investment that increases productivity and profitability and is part of an approach towards Operational Excellence. In this post we want to look at the practical and human considerations of the service maturity model from the point of view of the service provider. What methods and technologies do we and our customers need to adopt to move up the hierarchy? How do we better leverage the problem-solving skills of humans alongside technological innovation?

Connectivity

Each higher level in the hierarchy requires greater connectivity and the exchange of more information to create the actionable insight that delivers value. At the lowest level, the information exchanged consists primarily of a call to request repair of a broken pump. At the top level, equipment is extensively connected, with built-in sensors monitoring all aspects of performance and information flowing freely to characterize not only pump operation but also the process application and operational context. Why is this connectivity so important and how does it allow us to add value?

- As we bring more smart devices and advanced technologies into our service organization, the availability of the right information to the right person at the right time becomes increasingly powerful in achieving productivity goals. Combining the service engineer’s domain knowledge with immediate access to the pump’s performance history permits faster, smarter decisions. As connectivity grows, we will rely increasingly on smart apps at the point of service and on the use of advanced technologies like artificial intelligence to filter the data and provide actionable information. All of this requires that we and our customers move away from data silos towards greater access and harmonization.

- Technologies like block-chain can provide visibility throughout the supply chain, enabling cost savings and more efficient business operations in areas such as logistics, inventory management, and transport between the customer site and our service technology centers.

- Detailed knowledge of product and process history enables advanced life-cycle management and the use of preventative and prescriptive maintenance recommendations. For example, one of our customers achieved a 25% increase in pump lifetime by transitioning from a time-based maintenance schedule to a condition-based maintenance plan that integrated equipment monitoring with predictive maintenance (PdM), remaining-useful-life (RUL) technologies and changes to operating parameters to reduce the rate of fault development.

- Applying advanced analytics to product and process data is the foundation of all continuous improvement programs.

One of the greatest impediments to increasing equipment connectivity and the free flow of information is the parallel need for increasing trust, a most human quality. Traditionally, our industry has been reluctant to share information. Of course, there are legitimate reasons to be careful. In a competitive marketplace where success is determined largely by technological expertise, it is critical to preserve the security and confidentiality of process information. But technologies exist that allow secure sharing with trusted partners, and the benefits of sharing (lower costs and higher productivity), increasingly outweigh the potential risks as we move up the service maturity hierarchy.

Smart tool kit to empower service teams to reach their full potential

How should we equip our field service personnel to help them turn the information made available by increasing connectivity into high-value, actionable insights? The right tools can provide significant gains in efficiency, safety and quality. At Edwards we have a team dedicated to developing operational technology for our field service personnel. Some of the tools we are actively developing or exploring include:

- Autonomous Mobile Robots (AMR) to deliver pumps from storage to point-of-use precisely when needed, eliminating non-productive time the field engineer would otherwise spend moving the pump, reducing risks of injury from handling heavy pumps, and integrating with the site inventory management system to ensure that there are enough pumps to meet demand in a proactive maintenance model.

- Tablets or laptops loaded with apps to access equipment and process history, analytical tools, knowledge bases, standard operating procedures, and other resources.

- Safety wearables to monitor the environment for noxious gases and alert the wearer upon entering a high-risk zone.

- Audio visual headsets to enable hands free viewing of procedural instructions (perhaps including augmented reality) and to facilitate enhanced interaction with off-site, high-level support personnel and technical resources.

- Cobots (collaborative robots) to assist in handling heavy or awkward parts and assemblies or to provide remote visual inspection from off-site.

- 3D room scanning to provide up-to-date information about pump access and potential obstacles.

We expect to see factory trials of AMR for pump delivery, tablet devices and safety wearables in the very near future. Our long-term vision is to use technology to drive productivity and safety improvements throughout the sub-fab environment.

Actionable insight for faster problem solving

Imagine a future scenario where a field service engineer is at a customer site to resolve an issue with a pump on an integrated vacuum and abatement system. The engineer is equipped with a tablet, vision system and safety wearable. The engineer can access pump data and standard operating procedures, and complete administrative tasks via the tablet. Prognostic tools provide support for operational decisions – is there some action required to ensure the pump will run until the next planned tool maintenance or should it be exchanged now?

If an immediate exchange is best, a command sent from the tablet to the guided vehicle network can deliver a pump to the tablet’s location. The engineer is then free to prepare for the exchange. When the pump arrives, the engineer can perform the exchange, knowing that if there is an issue, high-level support is available from factory experts using the tablet and a connected vision system. All the while, the engineer can feel safe in a potentially hazardous environment, knowing that wearable “smart” PPE is monitoring the environment in real-time, using RFID to warn of nearby hazards and sensors to detect noxious process gases.

All these new technologies provide our engineers access to information that allows them to make better decisions, work more safely and efficiently, and harness their domain knowledge and creativity to solve problems faster and create more value. It is important to emphasize that technology supports rather than replaces the creativity of humans.

Achieving manufacturing objectives

Human intuition, problem solving, and domain expertise are flexible assets that can be shaped to address business needs. Empowering humans with new technology will change the way our teams work in the sub-fab. Jobs will become richer as machines take over the more mundane tasks. People will have more time to use their creativity to solve problems and create value.

To enable our field teams to use operational technology effectively in the field we need to adapt working practices and use elements of the smart toolkit only where they will contribute value. One size will not fit all. It will not be practical to use all the new technologies at every site. Customers are different, and they must decide which tools fit into their differing approaches to Operational Excellence, where people, processes, and machinery work together to generate maximum value.

We also recognize the challenges posed by, and the need to respect, customers’ strict security policies. The trust required to reach the higher levels of the service maturity hierarchy can only be built on a history of performance, a record of successful problem solving, and demonstrated expertise.

The outcome-based business models at the top of the service maturity hierarchy, which share risks and benefits between customer and provider, hold the greatest potential for leveraging human creativity and technology to create economic value. Delivering on this potential requires collaboration and trust between customer and provider at all levels of the business. Collaboration and trust among technical, operational, commercial, and leadership teams, in turn, rely on mutual respect and appreciation of the creativity and expertise of people. While smart technology, intelligently, deployed can multiply returns, value derives ultimately from the very human aspirations and creativity of an organization’s greatest asset – its people.

If you are interested to find out more on Operational Excellence you can find useful tools and resources on the Edwards Innovation Hub, edwardsinnovation.com/operational–excellence

Acknowledgements – I want to thank Richard Salloum and Reuben Day for their valuable insights and contributions to this discussion.

*Edwards Service Maturity Infographic is a resource to help organizations evaluate their approach to vacuum and abatement maintenance.