SHINSUKE KITAZAWA, Junkosha Inc., Tokyo, Japan

Ultra-high vacuum in a processing chamber is generally achieved using a turbomolecular pump located at the processing tool followed downstream by a dry vacuum pump usually located within the sub-fab environment. These sensitive process chambers demand high performing materials and that includes the cabling used for data and power.

In order to achieve stringent new requirements, there are some essential ground rules that need to be considered in the context of semiconductor manufacturing and components R&D. Materials scientists agree that the optimum solution for use in vacuum environments would ideally be based on ceramic materials due to their low outgassing rate. Plastics are generally avoided in high vacuum applications because of their relatively high outgassing rate. Fluoropolymer derivatives, however, provide flexibility and reduced potential for outgassing.

In many applications it is necessary to run wiring inside a vacuum chamber. In principle, coaxial cable can be made with a ceramic insulator; however, these are relatively expensive and as rigid structures are subject to micro-phonics (where certain components in electronic devices transform mechanical vibrations into an unwanted electrical signal). Plastic parts could be desirable where thermal isolation is required. Metallized plastics in the form of superinsulation may be needed as thermal radiation shielding. In situations where the use of plastic in a high vacuum application is desirable, there are steps that can be taken to reduce its impact on the vacuum level.

Before considering the use of plastic components, the question of service temperature must be addressed. High temperatures will be encountered if the system is to be baked out or if devices such as evaporation sources are present. PTFE may be used at temperatures as high as 260°C, however, most plastics are limited to much lower temperatures. When current carrying wires are used under vacuum they will be cooled by conduction only and the current carrying capacity must be de-rated.

To minimise the impact of a plastic component on the ultimate pressure and pump-down time one would start by choosing plastic that is not hygroscopic (i.e. as substance that attracts and absorbs water molecules). Polyethylene, polypropylene and t fluorocarbon polymers (FEP, PTFE, PFA) are examples of plastics which are not hygroscopic. This requirement has engaged technologists in a series of product developments including PTFE. A breakthrough, based on two years of work in research laboratories in Japan, is taking cabling to a new level, based on a new ePTFE, dubbed as SLO (Super Low Outgas) cable. Junkosha’s solution combining ‘super’ low outgassing cables with flexibility and integration of multiple cables makes it ideal for applications with moving parts in vacuum chamber environments ranging from motors to encoders.

Importance of reduction of outgassing in vacuum environments

Outgassing rates for plastics are often reported as TML (Total Mass Loss) and CVCM (Collected Volatile Condensable Material). The total mass loss is the percentage of mass lost after the sample is heated to 125°C under vacuum for 24 hours. The CVCM is the fraction of mass condensed on a nearby test surface at 25°C.

The TML and CVCM provide a means of comparing different materials for their suitability for use in vacuum. To predict the actual pressure that would be achieved in a system, or to calculate the pumping speed required to achieve a desired pressure, we require an outgassing rate expressed as (volume x pressure) per unit area per unit time. These values have been compiled for several materials. A fresh PTFE surface, for example, is reported to have an outgassing rate of 1.7 x 10-7 Torr-Liter/sec-cm2 at 25°C after 1 hour under vacuum. In a system with an effective pumping speed of 100 l/s, a 100 cm2 PTFE surface would contribute 1.7 x 10-7 Torr to the pressure. After 10 hours the outgassing rate for a fresh PTFE surface falls to 3.3 x 10-8 Torr-Liter/sec-cm2. By comparison, the outgassing rate for nylon is approximately 100 times higher, while outgassing rates for clean, baked stainless steel surfaces are typically reported to be 3 x 10-12 Torr-Liter/sec-cm2. Outgassing rates are strongly temperature dependent.

Extreme high vacuum (EHX) or Ultra High Vacuum (UHV) chambers are typically constructed of stainless steel, aluminium or titanium. As cited by vacuum chamber and components manufacturer, Anderson Dahlen, various heat and surface treatments are typically employed to achieve low outgassing rates. Commercial vendors of vacuum chambers rarely report or specify outgassing rates of chambers, mostly because of the difficulty and expertise required to perform such measurements. It is often difficult to compare published outgassing results using various techniques because different studies use different chamber geometries, environments, and poorly defined or implemented measurement techniques. There is no consensus on the best, most efficient way of producing vacuum chambers with ultra-low outgassing rates.

There are many application areas for SLO cabling, including EUV lithography, mask (reticle) inspection, wafer inspection, sputtering, dry etching and ion implantation. In a scanning electron microscope, for example, outgassing particles can affect the quality of the image. By deploying a SLO cable, there will be less/zero outgassing molecules to latch on and affect the image quality.

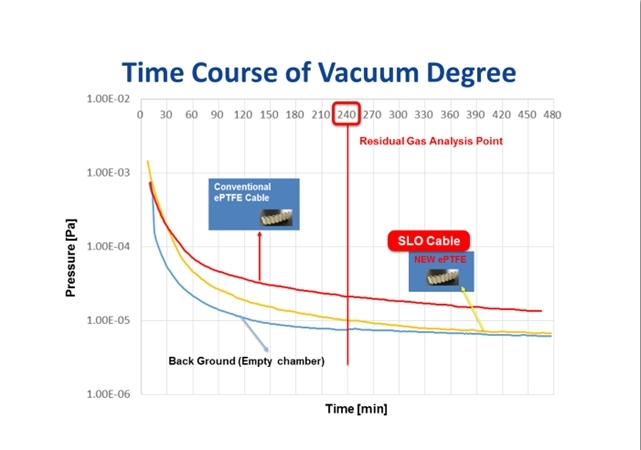

An exhaustive series of tests in several vacuum environments were undertaken at Junkosha’s R&D facilities. The results, shown in Figures 1, show SLO can achieve Ultra high vacuum (10-5Pa) and shorten the time to arrive at the ultimate pressure.

SLO cables enable manufacturers to achieve the level required in the vacuum in a reduced time. This provides the environment with ambient pressure via the pump deployed to create the vacuum suitable in which to use the cables and other polymer-based products which do not emit outgas.

Conclusion

In using the ultra-high vacuum, manufacturers seek to reduce the amount of time it takes to get to 10-5 Pa and essentially want to take the least amount of time to get there. The SLO cable allows for the user to reach that ultra-high vacuum level in a reduced amount of time, whereas, if one uses a conventional cable, they might not even be able to reach the goal of creating an ultra-high vacuum.