As microelectronics have become an essential part of modern society, greenhouse gas emissions associated with their manufacture and use have increased in tandem. Semiconductor manufacturing is reported to contribute 31% of global greenhouse gas emissions, and a U.S. Department of Energy analysis of data from the Intergovernmental Panel on Climate Change estimates greenhouse gas emissions associated with semiconductors could quadruple by 2030.

Research to reduce this essential field’s environmental impact is now underway with teams of students from the Ira A. Fulton Schools of Engineering at Arizona State University. They are exploring ways to make microelectronics manufacturing more eco-friendly, and their work is sponsored by TSMC, one of the world’s largest semiconductor manufacturers with an increasing presence in Arizona as part of the industry’s rapid expansion.

Potential shines brightly for diamond electronics

Undergraduate students in the Fulton Undergraduate Research Initiative, known as FURI, work with faculty members to apply knowledge gained in the classroom through hands-on research experience. TSMC funded eight FURI projects related to semiconductor manufacturing in the fall 2024 semester, some of which focused on increasing the sustainable use and manufacturing of semiconductors.

Fulton Schools electrical engineering student David McComas’ sponsored project focuses on reducing the energy consumption of power electronics and radio frequency, or RF, electronics. Power electronics convert and regulate electricity to ensure the proper amount and type are used in electrical devices, and RF electronics are used for communications technology.

McComas is exploring the use of diamond static induction transistors. Transistors in RF devices amplify electronic signals for transmission in telecommunications and radar systems, while transistors in power electronics control electric current flow.

Diamond has promise as a semiconductor material due to electronic properties that are improvements over other materials commonly in use. These properties include the highest known thermal conductivity for a material, resulting in high levels of heat dissipation and reduced cooling requirements; a high breakdown field, which results in less material needed to handle high electrical voltage; and a wide bandgap, which means the material can output more power while withstanding high temperatures from the heat generated by its use.

The application of diamond as a semiconductor material also reduces power loss throughout devices that use it, resulting in less electricity required to power diamond devices.

“We can create a new generation of smaller, faster, more efficient and more sustainable devices than those we use today,” McComas says.

This decreased electricity use has the potential to improve environmental impact, as power generation accounted for 25% of U.S. greenhouse gas emissions in 2022, according to the U.S. Environmental Protection Agency.

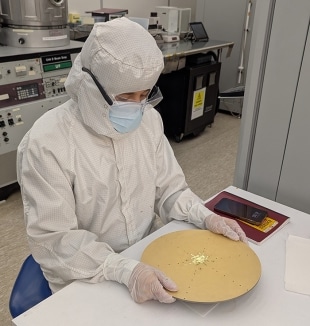

McComas’ FURI project involves simulating the operation of diamond microelectronics on the ASU Research Computing Sol supercomputer, part of ASU’s Core Facilities for research, by using technology computer-aided design, or TCAD, software. He then analyzes the performance of the simulated devices to plan a process for fabricating prototypes in the ASU NanoFab, a semiconductor fabrication facility on the Tempe campus that is also part of the Core Facilities.

By testing different device designs under the supervision of Nidhin Kurian Kalarickal, an ASU assistant professor of electrical engineering, and Kalarickal’s doctoral students, McComas aims to maximize performance benefits derived from the use of diamond materials.

As a student in ASU’s Barrett, The Honors College, McComas has made the project part of his required thesis work. His fall 2024 FURI research built on his spring 2024 FURI project, and he plans to continue researching the viability of diamond static induction transistors and their applications in the NanoFab during spring 2025.

After he graduates in the spring, McComas aims to continue researching diamond electronic devices.

“I have three long-term hopes for this project,” he says. “The first is that diamond devices be used to build a more powerful and robust wireless infrastructure in the U.S. and globally. Next, that the study contributes to the field of diamond manufacturing and catalyzes further innovation. Lastly, that systems and circuits engineers use the devices to solve unique and unexpected problems.”

Reducing electronics manufacturing emissions at the source

Fulton Schools chemical engineering undergraduate student Jay Schroeder decided to focus his sponsored FURI project on a different aspect of semiconductor sustainability: reducing the production of greenhouse gas emissions during manufacturing.

Under the supervision of Shuguang Deng, an ASU professor of chemical engineering, Schroeder is exploring the efficacy of porous, crystalline materials known as zeolites at adsorbing a gas called tetrafluoromethane, which is used during the etching process in semiconductor manufacturing. Etching is when parts of semiconductor material are removed to allow for the placement of other components later in the manufacturing process.

Tetrafluoromethane is a greenhouse gas that causes approximately 6,500 times as much atmospheric warming as carbon dioxide. Current semiconductor manufacturing methods capture the gas via cryogenic distillation, where the gas is compressed and frozen to ensure it doesn’t escape into the air.

But the process doesn’t capture all emitted tetrafluoromethane, and it requires high amounts of energy to do so. By contrast, zeolite materials can bind the gas molecules to them with little to no electricity while leaving a smaller amount of tetrafluoromethane uncaptured, if any escapes at all.

“The gas would just have to pass over the surface, with or without electricity, and the surface would bond to the tetrafluoromethane, removing it from the air and holding it on the zeolite surface, much like how exhaust passes through a catalytic converter on a car,” Schroeder says.

He is exploring the predicted efficacy of different zeolite materials using density functional theory, which calculates the expected yet unconfirmed properties of materials. Schroeder uses the theory to narrow down which zeolite materials are likely to perform well for tetrafluoromethane capture, then simulates the expected performance through Grand Canonical Monte Carlo methodology to more accurately predict zeolite behavior.

After Schroeder completes his portion of the project by running simulations, Deng will use the results to determine which zeolite materials to physically test with graduate students in a lab setting under a variety of conditions.

Building a future of more ecologically friendly electronics

Deng says sponsorship from TSMC has enabled an increased number of research opportunities.

“TSMC’s commitment to supporting sustainability-oriented research at the undergraduate level is truly commendable,” he says. “This funding not only advances semiconductor sustainability, but also strengthens the broader science, technology, engineering and math ecosystem by investing in young researchers poised to drive future innovations.”

As a FURI project mentor, Deng encourages undergraduate students to get involved in semiconductor research through the program.

“Projects like these provide technical experience and help students understand the importance of sustainable practices in technology-driven industries,” he says. “Working on industry-backed research also provides valuable insight into potential career paths and strengthens problem-solving skills that are highly sought after in the semiconductor sector.”