TECHCET—the electronic materials advisory firm providing business and technology information—announces that the global market for wet metal deposition materials including electro-chemical deposition (ECD) and plating (ECP) chemistry blends in 2020 is forecast to be US$63 million. From semiconductor fabrication at wafer-scale in the Front-End Of Line (FEOL) to wafer-level and die-level advanced packaging, specialized copper (Cu) chemistry blends are seeing compound annual growth rates (CAGR) in demand of 11-13% over the period 2019- 2024. While on leading-edge logic chips, cobalt (Co) plating is used to make the smallest connections to transistors, as detailed in the latest Critical Materials ReportTM (CMR) quarterly update on Metal Chemicals for FEOL & Advanced Packaging.

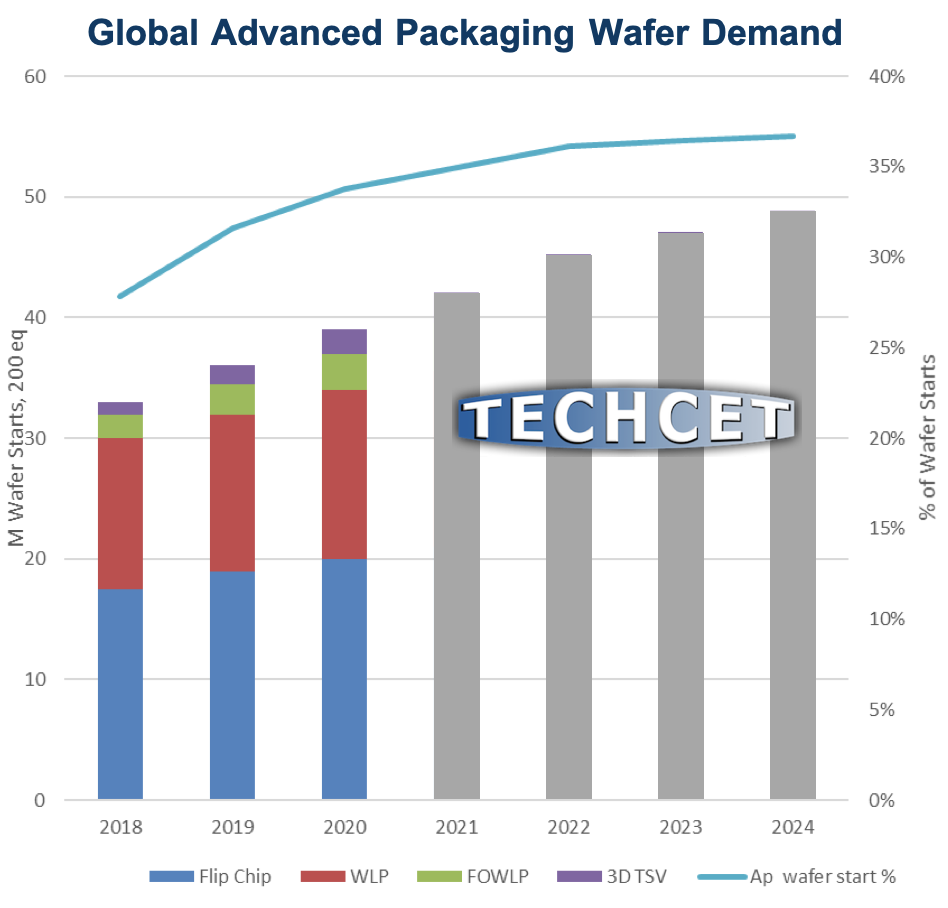

While 2/3 of chip packing today still uses relatively simple wire-bonding, TECHCET sees demand for advanced packaging—including flip-chip (FC), fan-in wafer-level packaging (FIWLP), fan-out wafer-level packaging (FOWLP), and through-silicon vias (TSV)—to grow at a strong 8.9% compound annual growth rate (CAGR) over the period 2019-2024 (Figure). These advanced packaging interconnects will continue to use plated solder formulations of tin (Sn) and tin-silver (SnAg), while demand for Cu plating chemistry for interconnect “bumps” and re-distribution lines (RDL) is expected at 11% CAGR over the same period.

“While advanced packaging interconnects are adding more value to final system function, improved metal lines are still needed on most advanced IC chips in heterogeneous integration,” explained Terry Francis, TECHCET Director of Technology and Senior Analyst and author of the report. “On-chip copper metal constrains the speed of the densest ICs today, which has led to use of cobalt in the lower metal layers in 10nm-node and smaller logic devices.”

This report covers the following suppliers: Atotech, BASF, Dow/DuPont, Ishihara, MacDermid/Enthone, Materion, Moses Lake, Soulbrain, Shinhao, Uyemura.